As consumers, we’re delighted with each new wireless innovation that enters the market – like when we can take calls from a watch or when our children control their toy robot from a smartphone. As far as we’re concerned, the more connected the device, the better. But when we switch positions from consumer to test engineer or from consumer to manufacturing operations manager, that delight is quickly replaced by anxiety. We’re apprehensive about being able to ensure product quality in the face of increasing product complexity and pressure to reduce test costs.

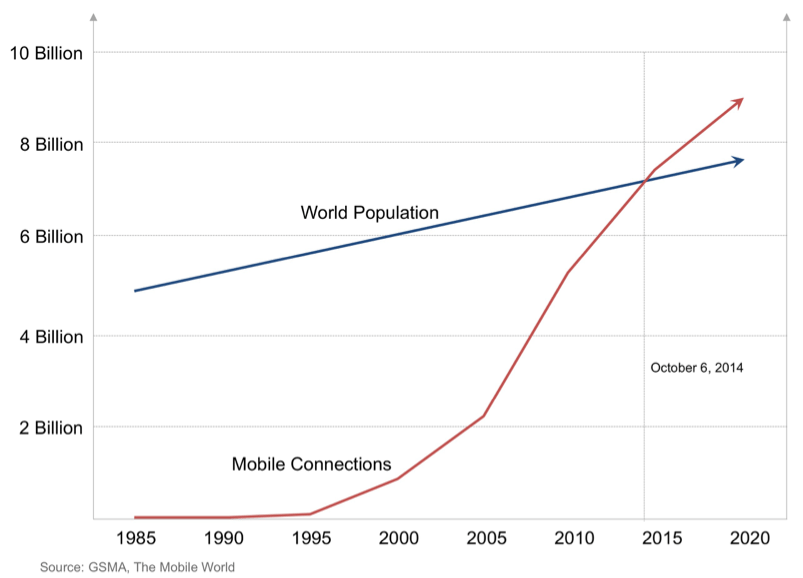

We’ve heard the stats. Today, the total number of mobile connections in the world exceeds the total number of people. Looking into the future, ABI research predicted that by 2020, there will be more than 40 billion connected wireless devices. Similarly, GSMA recently predicted that by 2020, 9 billion mobile radios will connect to our cellular infrastructure.

Figure 1: Mobile vs. population growth, 1985-2020.

Increasing wireless adoption fundamentally changes the cost dynamics of producing wireless devices. Manufacturers are pressed to dramatically reduce production costs and increase capacity. However, the wireless devices themselves are only becoming more complex. As a result, the need to lower test costs continues to drive significant innovation in the test and measurement industry. Not only has this market pressure driven the need for lower-cost instruments, but it also has driven a range of various new test techniques.

Increasing wireless complexity

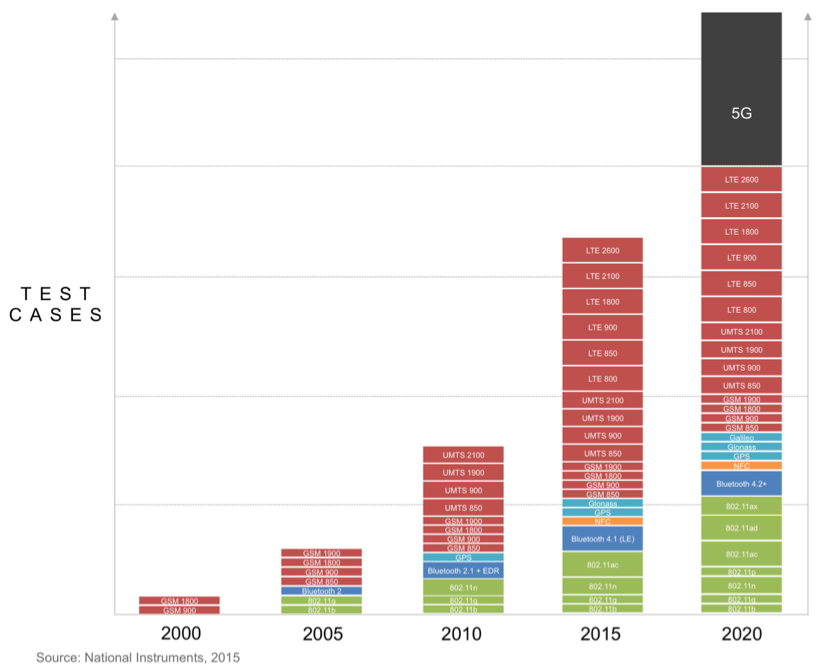

Higher device complexity increases test complexity and, without test innovation, results in higher test costs. Over the past 20 years, one of the most telling examples of increasing device complexity can be observed in the number of bands and cellular standards used in a mobile device.

In 2000, it was common for a mobile phone to support two GSM bands. By 2005, mobile phones were using four GSM bands (marketed as “world band phones”) in addition to Bluetooth and Wi-Fi technology. By 2010, UMTS technology was beginning to augment the GSM/EDGE radio – and testing UMTS required completely new test cases. The trend of increasing wireless complexity has continued over the past five years with the rollout of LTE, 802.11n/ac and even NFC.

Figure 2: Dramatic rise in mobile phone radio complexity over two decades.

Looking forward to 2020, device complexity will continue to grow. The industry may yet see widespread adoption of additional Wi-Fi technologies such as 802.11p, 802.11ad, 802.11ah and 802.11ax. In addition, the fifth generation of cellular communications is likely to produce test challenges that far exceed that of LTE.

Current 5G research areas include the use of millimeter waves, new waveform types, new network topologies and massive multiple-input, multiple-output. Should millimeter waves or massive MIMO become adopted as part of an official 5G standard, mobile device testing will get substantially more difficult and more expensive. More specifically, these wireless technologies will require test organizations to upgrade existing test infrastructure to support wider signal bandwidths, higher frequencies and more antenna ports. Of course, these test requirements are in addition to the fact that 5G will also add new test cases.

Declining cost of wireless

At the same time that wireless device complexity has continued to grow, the cost expectations of wireless technology have continued to decline. In 1983, the first commercial mobile phone – the Motorola DynaTAC 8000x – retailed for $3,995, which is almost $10,000 in today’s dollars. By 1990, a mobile phone cost less than $1,000, and by 2000, a low-end mobile phone was priced at around $200.

Although the rate of decline in mobile phone ASPs has slowed due to the increased value of smartphones, the price of the core wireless technology continues to decline. An excellent proxy for this was the 39% decline in ASP of Nokia phones from 2005 to 2009 – a period over which smartphones represented a relatively low percentage of units shipped.

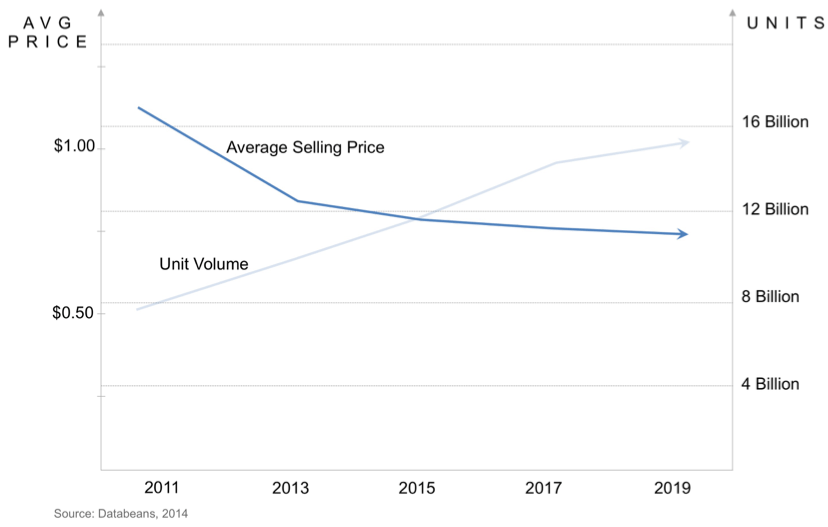

One of the most telling indicators of the “cost of wireless” can be observed by evaluating the ASP of the semiconductor components themselves. In fact, recent market forecasts by both Databeans and IC Insights predict that the ASP of mobile device analog ICs will decline by more than 30% from 2011 to 2019.

Figure 3: Wireless analog IC cost and unit volume from 2011 to 2019.

Yet, the challenge of testing wireless devices requires a test approach that is more extreme than a mere 30% improvement in test efficiency. Coupled with the dramatic increase in device complexity, test efficiency must outpace both the challenges of test complexity and target test cost.

Factors such as increasing cellular bands, new waveform types and more Wi-Fi configurations invariably lead to more test cases. Thus, the real challenge for today’s test engineers is to not validate the same number of test cases for 30% less, but to validate across 10x or 100x test cases for at least 30% less.

The impact on test

Although the idea of more connected, less expensive, and higher throughput wireless devices is certainly appealing to us as consumers, it is dramatically changing how wireless devices are tested.

A decade ago, mobile phone testing required an instrument to literally place a cellphone call with the mobile device. This approach, now called “signaling test” requires a call to first be established before actual testing can take place. In some instances, phone calibration and testing can take 10 minutes or more.

More recently, the mobile phone industry has shifted to the use of “non-signaling test.” Using this approach, a PC can send a series of commands to the mobile device over a digital interface to get into a “test mode.” Although non-signaling test has proven to be a faster approach to device testing, engineers continue to innovate with faster test methods.

Today, both cellular and Wi-Fi chipset vendors are increasingly cooperating with test equipment vendors to enable faster methods of wireless test. For example, new “fast sequencing modes” on modern wireless chipsets sequence through various test cases more quickly. This technique can be combined with faster instrumentation to test a wireless device more quickly and less expensively.

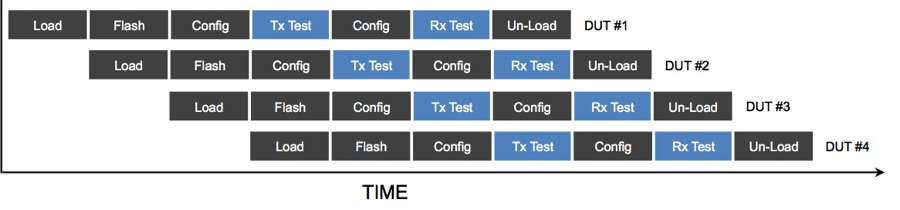

Figure 4: Parallel test enables more efficient utilization of test equipment.

Going forward, the next major innovation in wireless test is the use of massively parallel or pipelined test architectures. These test architectures reduce manufacturing costs by enabling manufacturers to test multiple devices in parallel to better utilize capital equipment. Today, an industrywide shift is underway to replace one-up (system test one device at a time) or two-up test stations with more cost-effective four-up and eight-up alternatives. Tomorrow, systems that test no fewer than 16 or 32 devices in parallel will no longer be cost-effective.

The future

With increasing device complexity, wireless device test will continue to require new approaches to test and measurement. As Frost & Sullivan Analyst Olga Shapiro recently stated, “To remain profitable in the future, companies will need to rethink their approach for wireless test and embrace new paradigms.”

Fortunately, the past decade has seen dramatic improvements in key instrument technologies such as CPUs, FPGAs, VCOs, DACs and ADCs. These improvements not only allow modern test equipment to deliver increasingly better analog performance – but also deliver increasingly faster measurement speed.

As one might expect, part of the solution for tomorrow’s wireless test challenges is a combination of lightning fast instrumentation, a new approach to wireless test and the engineering expertise required to put it all together.

David Hall is principal product marketing manager at National Instruments. david.hall@ni.com.

Editor’s Note: In an attempt to broaden our interaction with our readers we have created this Reader Forum for those with something meaningful to say to the wireless industry. We want to keep this as open as possible, but we maintain some editorial control to keep it free of commercials or attacks. Please send along submissions for this section to our editors at: dmeyer@rcrwireless.com.