Unlike previous generations of passive sensors, the “internet of things” will allow a supply chain to control the external environment and execute decisions, according to the Gartner article Five Ways the Internet of Things Will Benefit the Supply Chain. With the IoT, sensor-embedded factory equipment can not only communicate data about parameters such as the temperature and utilization of a machine, but also change equipment settings and process workflow to optimize performance.

According to Noha Tohamy, research VP at Gartner, in order to profit from the IoT, chief supply chain officers need to leverage analytics and define new processes along the entire supply chain, with the ultimate goal of fulfilling customer demand for digital and information products and services.

Industrial IoT supply chain considerations

Tohamy outlined five rules CSCOs must follow for success:

Pursue the IoT at any demand-driven value network maturity level

The ability of an organization to benefit from the IoT is not predicated on higher maturity levels. However, the magnitude of those benefits will be impacted by those levels, Tohamy said.

Take, for example, a consumer products manufacturer that plans to implement telematics to allow the organization to capture information on the location and conditions of its transportation equipment.

“While a functionally siloed company would be able to apply the IoT use case to capture efficiency and cost reduction improvement; a company with an integrated supply chain would benefit from the same technology to further improve overall supply chain performance and to become demand-driven,” Tahomy said.

Leverage the IoT to improve existing supply chain processes

As well as being a driver for business and supply chain transformation, IoT also can drive incremental benefits to existing supply chain processes spanning asset utilization, warehouse space optimization or production planning.

Consider the potential for IoT to fully redesign existing supply chain process

The proliferation of the adoption of IoT will drive the need for the redesign of many existing supply chain processes – an industrial equipment manufacturer that has redefined its customers’ value proposition from selling pure physical products to offering a complete solution that spans physical products, embedded software and combined services, for example. In this business model, a supply chain process like sales and operations planning must now account for the customers’ demand for the complete solution.

Assess the potential for offering IoT-enabled information products to internal and external clients

“With the IoT, the supply chain will have unprecedented access to data valued by internal and external stakeholders,” Tohamy told Gartner. “This presents an opportunity for supply chain groups to co-develop new information-based solutions for individual customers or markets.”

For example, an agricultural equipment manufacturer can capture data from sensors on agricultural equipment to understand how farmers are using different product features. This information can be shared with the research and devlopment groups to develop products that best meet customers’ needs.

Build strong supply chain technology leadership to support the convergence of the digital and physical supply chains

Infusion of IoT in the supply chain will create new challenges and demands on the supply chain organization, which will likely be tasked with delivering, sourcing and maintaining technology-enabled products and solutions.

“This presents a great opportunity for the supply chain to play a critical leadership role in defining the overall digital business strategy,” Tohamy said. “To do that, the supply chain organization must acquire senior technology skill sets and leadership with the companywide credibility to define strategic technology direction. These skill sets must go far beyond those with the traditional focus on providing tactical support to supply chain functions.”

Now that we have gone over some considerations when using IoT in a supply chain environment, it is time to outline some potential use cases for using IoT for production and distribution.

IoT supply chain use cases

Increased logistics transparency

The IoT can make information about transport available to the entire supply chain, making the chain more transparent, according to researchers at the University of Houston. The smart items monitor the goods and proactively raise an alert if transport conditions are not appropriate anymore, so the carrier is alerted and the goods have a higher chance to be saved. This reduces the costs of return, the removal of defective goods and lowers transports due to lower reshipping rate.

In-transit visibility

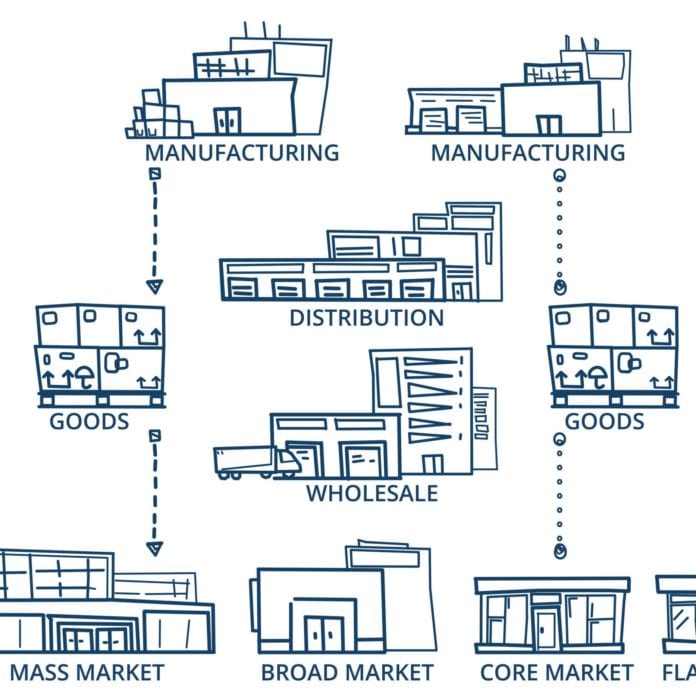

One area that will play a prominent role in the future supply chain, as it’s impacted by IoT, is in-transit visibility. The logistics ecosystem has many players, and thus, many moving parts, according to Inbound Logistics. Products are handled and transferred among the manufacturer, suppliers, the distribution center, retailer and customer.

Key to in-transit visibility are cloud-based GPS and Radio Frequency Identification technologies, which provide identity, location and other tracking information. These are the backbone of IoT as it relates to the supply chain. By tapping the data gathered by these technologies, detailed visibility of an item is provided all the way from the manufacturer to the retailer. Data gathered from GPS and RFID technologies not only allows supply chain professionals to automate shipping and delivery by exactly predicting the time of arrival; they can monitor important details like temperature control, which impact the quality of a product in-transit.

Gathering the data to decrease operating expenses

Internet of things means richer data and deeper intelligence for all parties in a supply network. And that doesn’t just apply to product visibility. According to Inbound Logistics, by allowing devices to “talk to each other” in the right way, IoT can help supply chain professionals:

- Reduce asset loss

- Know about product issues in time to find a solution.

- Save fuel costs

- Optimize fleet routes by monitoring traffic conditions.

- Ensure temperature stability

- Monitor the cold chain. According to the Food and Agriculture Organization of the United Nations, about one-third of food perishes in transit every year.

- Manage warehouse stock

- Monitor inventory to reduce out-of-stock situations.

- Gain user insight

- Embedded sensors provide visibility into customer behavior and product usage.

- Increase fleet efficiency

- Reduce redundancies – deadhead miles account for up to 10% of truck miles, according to the Environmental Protection Agency, and 28% for private fleet trucks, according to the National Private Truck Council.