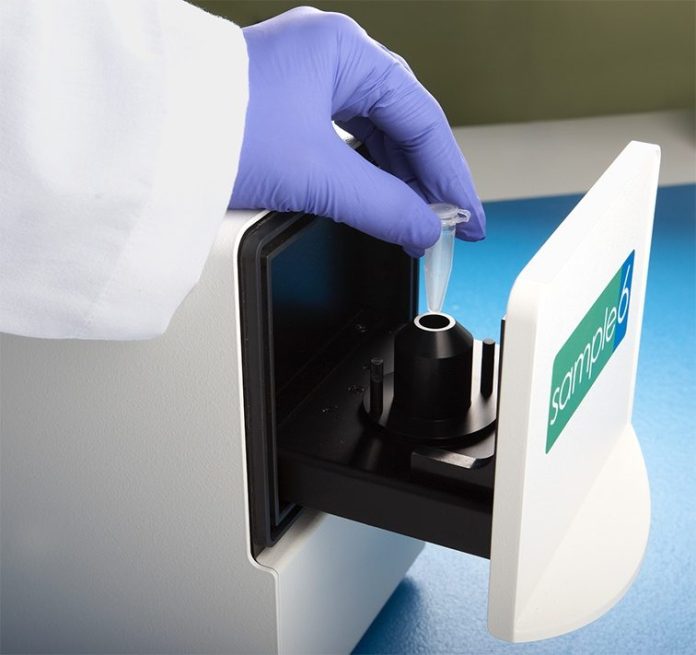

The internet of things can make food safer, but no one wants to eat food with sensors embedded inside it. Instead, food processors and distributors are using advanced diagnostics to test food on site before retailers sell it.

Unilever and Smithfield use test kits to check food for the presence of pathogens that could harm consumers. The kits are made by Sample6, a synthetic biology diagnostic startup based in Boston. Sample6 turned to another Boston startup, Elemental Machines, for a connected sensor solution which uses the AT&T IoT platform.

Sample6 tests biological samples and pathogens in order to create its kits, and these samples are stored in freezers that need to maintain temperatures of -80 degrees Fahrenheit in some cases. According to Sample6 founder Michael Koeris, temperature, air pressure, light and humidity are four variables that can significantly impact the integrity of his biological samples. He’s tried several lab monitoring systems, but he said the first one that worked came from Elemental Machines.

Koeris invested in two types of Elemental Machines sensors: some that monitor temperature exclusively, and “combo sensors” that monitor air pressure, light and humidity as well. He said some of the sensors cost more than $200 each, and that he’s also purchased three tablets that are used as gateways for data collection and for connection to a dashboard that highlights any potential problems in the lab. Altogether, Sample6 has invested more than $3,000 in the IoT platform, about $7,000 less than the company paid for its previous system, which Koeris said did not even include cellular backup.

Elemental Machines uses the AT&T network to guarantee an internet connection when Wi-Fi is not available. Koeris said he values the cellular connectivity because the Wi-Fi and internet service in his neighborhood can be unreliable. Elemental Machines also uses AT&T’s IoT platform and global SIM cards. Sample6 pays Elemental Machines a monthly fee for the services.

Koeris looks forward to the next evolution of IoT, which he says will be about predictive maintenance. His giant freezers are his biggest capital expense, and he wants advanced sensors to tell him when one of the compressors is nearing end of life. He said that it can cost $20,000 to replace a compressor in one of his freezers.

Sample6 says its goal is to create the world’s fastest food pathogen detection system. The company has raised three rounds of funding totaling $32 million, and its newest investor, Valley Oak Investments, specializes in the food industry.