Manufacturing execution system ups productivity at GE Aviation plant

GE Digital is focused on leveraging the industrial internet of things to drive digital transformation in various industrial sectors including manufacturing. It’s latest manufacturing execution systems (MES) software, which covers everything from pairing certified workers with particular pieces of equipment to generating detailed work instructions, makes possible what the company calls “paperless manufacturing.”

The new solution, Production Manager, helps manufacturers realized “reduced labor and material cost,” GE Digital VP of Digital Product Management Matthew Wells said, “and improved contribution margins and on-time delivery. These allow all manufacturers to stay competitive today and ensure success tomorrow.”

Like many of GE Digital’s products, the technology was developed internally to support GE’s larger industrial business. For instance, GE Aviation used Production Manager at one of its manufacturing facilities and realized an increase productivity by 1.95%. “Production Manager has been developed in GE’s own manufacturing businesses where we addressed these issues,” Well said. {It incorporates our best manufacturing practices, high-performance technologies and more than 25 years of MES expertise.”

The MES supports route management, order dispatch, personnel and machine qualification management, labor tracking, work instructions, document management, integration with machine automation systems and a customizable user interface.

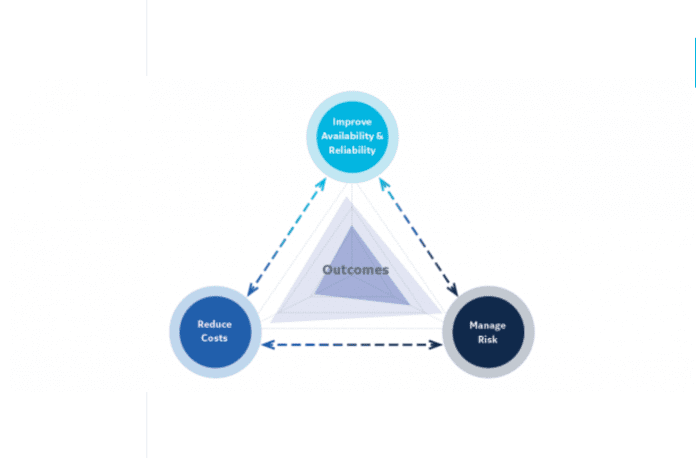

This comes on the heels of a July update to GE Digital’s asset performance management (APM) software, which can be deployed on-premise or as a cloud-based service built on the company’s Predix industrial internet of things platform. One of the key aspects of the APM is an “always-on unified view” of machinery health. According to the company, “With real-time contextual views of asset health, status and issues from the edge, the cloud or a hybrid environment, operators can efficiently take action.”