Factory owners who invest in automation can break even in less than six months and see a 210% return within the first year, according to Ericsson. The company backs up this marketing claim with real world experience from one of its own factories. A Chinese facility that makes Ericsson radio products has used low-power wide area cellular technology to automate processes and significantly reduce labor costs.

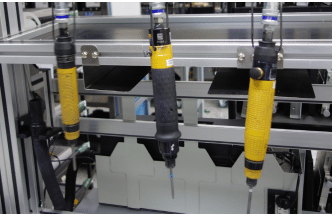

The Nanjing Ericsson Panda Communication Company is Ericsson’s largest industrial factory, employing more than 2,000 people. A thousand high-precision screwdrivers in the factory require routine calibration and lubrication based on utilization, a cumbersome manual process. Ericsson partnered with China Mobile to implement a narrowband IoT solution to replace these processes.

The high-precision tools were fitted with real-time motion sensors that were attached to NB-IoT modules. The data runs via a cellular IoT network over Ericsson Panda’s private cloud and back-end systems, which make automatic calculations and intelligent analyses of the collected data. The cloud-based quality-monitoring system tells Panda when certain thresholds are reached, which can extend the service life of the screwdrivers.

The Ericsson/China Mobile solution includes:

• Ericsson’s RBS6000, a multi-mode base station that is operated with a pre-commercial software that supports the cellular IoT technology

• Intel’s XMM 7115 modem embedded in a Fibocom module

• Cellular connectivity provided by China Mobile’s Jiangsu network

• A China Mobile software development kit used in tandem with the carrier’s OneNet IoT cloud platform

• Motion sensors supplied by ADI

The project has been so successful that Panda now plans to completely eliminate manual tracking of the high-value screwdrivers. The company believes it will be able to reduce the amount of manual work in the factory by 50%.

China Mobile and Ericsson are calling Panda the world’s first cellular IoT-based connected factory. Now they hope to take these types of solutions to customers.

“The combination of cellular IoT and Industry 4.0 has so far been fairly unexplored,” wrote Ericsson’s Chris Houghton, head of the company’s North East Asia region. “Enabling IoT network technology such as cellular LPWA, together with cloud-based solutions, gives manufacturing firms access to more information than ever before. The opportunity to use data to increase productivity is not only beneficial to a firm, but the whole of society as well.”

Follow me on Twitter.