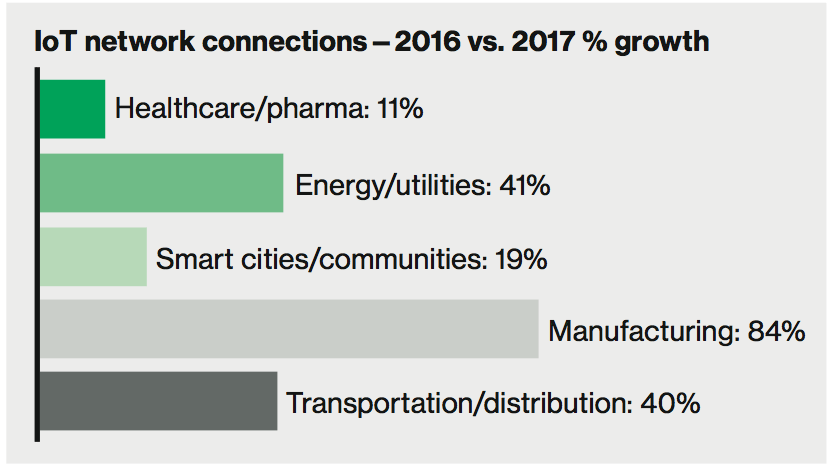

Based on Verizon’s annual “State of the Market: Internet of Things 2017” report, the manufacturing sector is leading the way in adoption of internet of things technologies with an 84% increase in number of year-over-year network connections. As digital transformation, based on IoT adoption, gives way to smart manufacturing, other high-value verticals like healthcare and utilities are still growing, but not at near the same rate. To better understand this dynamic, let’s take a look at how major players in the telecom, software and manufacturing ecosystems are investing in new product offerings to support this growth.

Orange Business Services, Microsoft partner on end-to-end solution

The two firms are collaborating to deliver end-to-end internet of things solutions to boost the digital processes of companies in the manufacturing sector. Through this partnership, enterprises can use the Orange modular solution, Datavenue, strengthened by Microsoft Azure IoT Suite, to transition to optimize the entire manufacturing value chain.

Use cases that can take advantage of this collaboration range from supply chain and smart inventory management to digital operations, such as predictive maintenance, employee safety and facility and equipment management.

One of the firms that has already implemented this new offering is e.l.m. leblanc, for which Orange delivered a customized IoT platform on Microsoft Azure, which provides a tailored solution for remote monitoring, along with predictive maintenance. Subsidiary of the Bosch Group, e.l.m. leblanc manufactures gas boilers and water-heaters.

Supporting the RF piece of private networks for manufacturers

From unlicensed industrial LTE networks based on MulteFire, to shared spectrum in the CBRS band supporting the connectivity needs of enterprise and industrial interests, not to mention full-blown 5G to facilitate high-end use cases like automated industrial robotics, Ericsson foresees smart manufacturing as a driver of investment in its portfolio of technologies.

Anders Svensson, principal solution manager at Ericsson, said the company expects customers to deploy private LTE networks to support smart factory operations. “It will be covering a certain manufacturer’s site,” Svensson said. “The aspect of controlling certain machines will be very local even if they might have long distance connectivity for remote control.”

GE Digital helping manufacturers go paperless

GE Digital is focused on leveraging the industrial internet of things to drive digital transformation in various industrial sectors including manufacturing. It’s latest manufacturing execution systems (MES) software, which covers everything from pairing certified workers with particular pieces of equipment to generating detailed work instructions, makes possible what the company calls “paperless manufacturing.”

The new solution, Production Manager, helps manufacturers realized “reduced labor and material cost,” GE Digital VP of Digital Product Management Matthew Wells said, “and improved contribution margins and on-time delivery. These allow all manufacturers to stay competitive today and ensure success tomorrow.”

Like many of GE Digital’s products, the technology was developed internally to support GE’s larger industrial business. For instance, GE Aviation used Production Manager at one of its manufacturing facilities and realized an increase productivity by 1.95%. “Production Manager has been developed in GE’s own manufacturing businesses where we addressed these issues,” Well said. {It incorporates our best manufacturing practices, high-performance technologies and more than 25 years of MES expertise.”

The MES supports route management, order dispatch, personnel and machine qualification management, labor tracking, work instructions, document management, integration with machine automation systems and a customizable user interface.

Panasonic enables real-time visibility on factory floors for Ionic EMS

Ionics EMS, a precision manufacturer of components for computers and internet of things devices, said it has chosen Panasonic’s smart factory solution to boost productivity. Panasonic says it has implemented an integrated line management system to connect a diverse range of machinery and enable real-time control over an entire factory floor. The company said it created the smart factory with three goals in mind: workflow automation, quality enhancement, and productivity gains.

“The electronics industry is in a period of major transformation, and companies are expected to deliver diverse products in a timely manner,” said Hiroyuki Aota president of Panasonic’s smart factory solutions company. Ionics EMS said central management of its smart factories will expedite its plans for global expansion. The company currently has manufacturing facilities in the Philippines and in the U.S.

The company said one key advantage of the Panasonic solution is the ability to connect machines made by different manufacturers, and analyze them all from a common control room. In the past, the machines were analyzed individually. Ionics EMS also uses “automatic model change-over” and “error recovery by remote,” both of which are enabled by the Panasonic smart factory solution.