Cloud-integrated software framework accelerates time-to-market for IoT devices

Whether its an asset tracking platform meant to follow materials across a production floor or a light monitor that helps lower energy consumption in an industrial facility, at the heart of every internet of things (IoT) device is a set of components that collect and process data and transmit that information, as well as other insightful information, onto the web. From there, bespoke dashboards, accessible via any device through a cloud service, can enable operators to monitor the health of connected systems while potentially predicting faults before operations are affected. But, given the fragmented nature of the IoT ecosystem, along with the variety of cloud solutions on the market, developers can have a difficult job gathering the necessary embedded systems to quickly and effectively develop an IoT solution.

Mentor’s Scot Morrison, general manager of embedded platform solutions, described the market dynamics in an interview with Enterprise IoT Insights. “The fragmentation is a major challenge for our customers, which are the device manufacturers. Integrating all these things together is an enormous scalability challenge. Then there’s the cost and the security…and how you manage these devices and keep them secure.” Cloud providers “all have proprietary solutions. The communication protocols are standardized at this point, but all of that interaction and on-boarding of devices and higher-level functionality is completely proprietary to each cloud provider.”

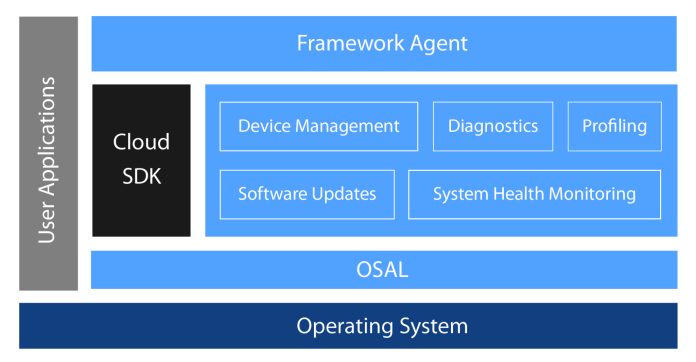

To help solve these problems, Siemens-owned Mentor developed what it calls the Mentor Embedded IoT Framework (MEIF), which provides native support for the Amazon and Microsoft Azure cloud services through those providers’ SDKs. Support for Siemens’ MindSphere is in the works, and further cloud services will be incorporated based on market demand. To further broaden potential adoption, Mentor took an operating system-agnostic approach for MEIF, which supports any processor architecture, including ARM and x86, according to the company.

MEIF supports device authentication and provisioning, configuration and control, monitoring and diagnostics and software updates and maintenance.

“The issue the manufacturer has is they have to look up at all these different cloud providers,” Morrison said. “They have to go out and buy a bunch of equipment and put it into the plant. They have this customization problem where they have to customize their equipment to work with the cloud provider the manufacturer is going to pick.” With the cloud SDKs, Mentor provides the tools that close what Morrison called the “IoT capability gap,” which includes integration with the operating system and hardware and portability to the runtime system.

Morrison continued: “For years, Mentor has invested in runtime platform and tools technologies to support the specific requirements of industrial and medical device manufacturers, such as safety certification, support for key industrial protocols, and enabling world-class security.” With MEIF, “We continue to extend our industrial market offerings by addressing a host of common challenges associated with security, portability, code re-use and multi-cloud requirements.”