Furthering the Industry 4.0 movement, Telefónica has teamed up with car maker SEAT and car-parts maker Ficosa to showcase an IoT-based supply-chain and manufacturing concept for the automotive industry.

The demo, one of many industrial IoT concepts from telecoms operators and vendors at Mobile World Congress (MWC) in Barcelona, is applicable to manufacturing and supply chain processes in all sectors, the company said.

The MWC initiative recreated a typical chain of supply and manufacture in the automotive sector, specifically, from the dispatch of rear-view mirrors, for example, by Ficosa in Spain through to the purchase of the SEAT vehicle by the end consumer in international markets.

Through the integration of the incoming digital technologies, Telefónica sought to show how enterprises could improve their industrial processes, including the automation of systems, and the traceability and immutability of goods within them.

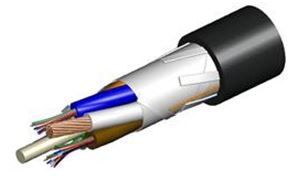

Technological components included IoT, private LTE, and pre-standard 5G connectivity standards, alongside blockchain and augmented reality (AR) technologies.

Vicente Muñoz, chief IoT officer at Telefónica, said: “Practically all industries and sectors rely on new technologies to improve their processes. The purpose is to be more efficient and secure, and even to improve forecasting of business needs.

“The industrial sector has specific security, real time decision-making and service quality requirements to which the connectivity of objects is learning to respond, using the IoT, the evolution of cellular networks and new processes, such as the blockchain.”

The demo proposes blockchain for the entire supply chain, from parts and assembly, through to final delivery in the market: IoT sensors detect and log in blockchain ledgers many of the events in the logistics process, including the status of assets during transport; document management and smart contracts are also recorded.

Telefónica also showcased a robotic arm, connected and controlled via private LTE through a pre-standard 5G network, in the assembly line. Telefónica showed how network slicing will permit enterprises to allocate distinct network capabilities to different services, despite running them on common infrastructure in the same spectrum.

The low latency of these next-generation technologies will also guarantee critical processes in the production chain, such as control of high precision tasks, it noted. Other LTE-based connectivity technologies, including low-power wide-area (LPWA) protocols like NB-IoT, LTE-M and CAT1, feature certain other characteristics for industrial settings, including lower battery consumption, better indoor coverage, and higher network density.

Telefónica also showed the application of AR on the factory floor, allowing engineers to carry out maintenance work with AR glasses, and a 5G video line to experts to assist with the maintenance, and even operation of equipment such as the robotic arm.

Muñoz said: “Our challenge as a company is to change people’s lives, and in this case, to help businesses become more efficient, assisting them to take decisions based on data and digitalise their processes to make them more efficient. This is the commitment that Telefónica have assumed.”