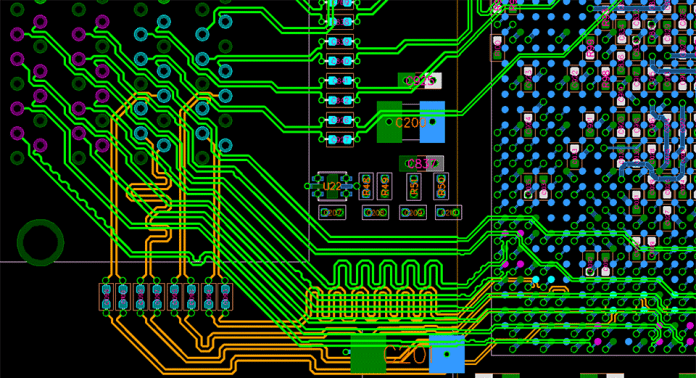

Siemens-owned software company Mentor Graphics has released a new design platform for engineers to twin and test printed circuitboard (PCB) prototypes virtually, before they are put into production, as the basis of embedded systems in assorted IoT devices.

The new platform, called Xpedition, provides the industry’s first ‘shift-left’ verification capability, enabling PCB engineering teams to test products at every stage of the design process, including in early drafting.

Mentor provides a variety of verification tools for PCB designers to identify problems with their designs, even during initial design drafts.

The new Xpedition platform offers ‘digital twinning’ functionality for non-specialist PCB designers, much like Siemens offers on a grander scale for industrial systems.

It comprises verification technologies for schematic analysis, signal integrity, power integrity, electrical rule checking, thermal simulation, vibration analysis, and manufacturability testing.

These can be applied within a single authoring environment to create virtual prototypes for quick simulations. The platform will shorten design schedules and reduce design costs, said Mentor.

A.J. Incorvaia, senior vice president at Mentor Electronic Board Systems, commented: “These integrated solutions enable verification within the design process to ease deployment, accelerate time-to-results, and allow our customers to maximise their investments.”

According to research by Lifecycle Insights, the average number of design re-spins is 2.9 per project, which translates to 16 days of unplanned development time and $82,000 in additional costs.

The study, quoted by Mentor, found PCB design teams taking a “shift-left” approach across their design processes realise a 14 per cent improvement in project delivery, re-spins, and overall design quality.

The Xpedition platform introduces automatic inspections of ‘schematic integrity’, in place of manual visual inspections. Mentor said the tool will eliminate re-spins early in the design by as much as 70 per cent.

Its new ‘design-for-test analysis’ tool identifies provides diagnostics on early-stage layouts, to also lower the cost of testing. The platform also claims improved ‘design-for-manufacturability’ analysis, covering fabrication, assembly, test, substrate and panel validation, and .

Better electrical performance sign-off will accelerate design reviews from days to just minutes, it said.