Nokia has agreed with NTT DoCoMo and Omron to run a series of joint field trials of 5G at production sites in Japan to assess the reliability of industrial 5G networks and the viability of modular “layout-free” production lines.

Nokia said in its announcement that manufacturing – out of all industries, and way ahead of the consumer market – will benefit most from 5G technology. John Harrington, president and chief executive at Nokia in Japan, said: “Whilst consumers will experience faster, more immediate mobile communications, it is manufacturers that are set to benefit the most from 5G.”

Nokia will provide the 5G equipment, Omron will provide the factory automation equipment, and NTT DoCoMo will manage the trials. Nokia said the trio will conduct “radio wave measurements and transmission experiments” to gauge network interference from the bustle of machines and people on the factory floor.

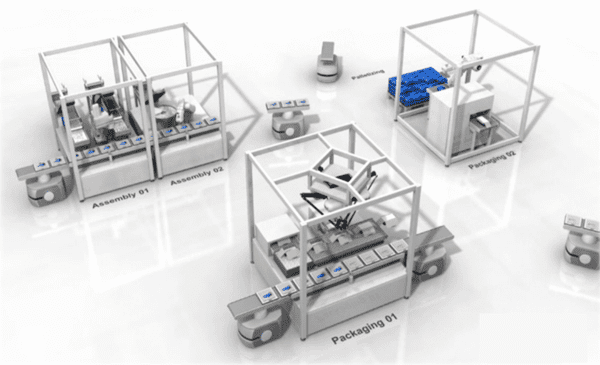

They will also test how to organise autonomous mobile robots (AMRs) in non-fixed production setups using 5G technology, to automatically convey components to where they are required based on communication with production line equipment.

The trials will make use of the low-latencies afforded by 5G technology, along with edge-based compute infrastructure, to ‘coach’ artficial intelligence (AI) software to optimise sensor-connected factory equipment. AI-enabled computer vision tools will be used to run video analysis of machine operators, to assess performance as well.

Nokia said the idea is to improve the training of technicians by detecting and analysing the differences of motion between more skilled and less skilled personnel.

Harrington commented: “The stable, lower-latency and higher throughput wireless connections that come with 5G allow them to truly embrace IoT. Production lines will be more flexible and adaptable, and productivity on the factory floor can be more easily improved.”

Takehiro Nakamura, senior vice president and general manager of NTT DoCoMo’s 5G Laboratories, said: “NTT DoCoMo has conducted multiple trials creating 5G use cases with a variety of partners, with factory automation emerging as one of the most interesting and challenging fields to explore.”

He added: “We are confident we will be able to prove the feasibility of layout-free factory production lines with autonomous mobile robots and person-machine collaboration.”

Shinji Fukui, executive officer and senior general manager for technology development within Omrom’s industrial automation business, said: “Omron is striving to create innovations in manufacturing through our technologies and solutions based on the industry’s widest range of control devices. This collaboration will enable us to create innovative solutions with 5G to address issues in the manufacturing industries.”

NTT DoCoMo announced last week it has joined the 5G Alliance for Connected Industries and Automation (5G-ACIA), to build 5G networks customised for specific use-cases and requirements.

The carrier said it wants to develop industrial 5G technology with the 5G-ACIA to optimise networks for factory automation. It aims to launch commercial 5G services across Japan by mid-2020.

Andreas Müller, chairman at the 5G-ACIA, from German firm Bosch, commented: “5G for industrial IoT has gained huge momentum since the establishment of 5G-ACIA in April 2018, and it has the potential to unlock huge economic opportunities in industrial production by enabling unprecedented degrees of flexibility, productivity and usability. By the same token, manufacturing is clearly one of the most attractive new fields of application for 5G.”