France-based industrial software provider Dassault Systèmes and China-based facilities management company Aden Group are combining their digital twin and modular architecture platforms to fast-track hospital construction.

The arrangement is in response to the COVID-19 pandemic. Dassault Systèmes was involved with China’s Central-South Architectural Design Institute (CSADI) to evaluate COVID-19 dispersal at Leishenshan Hospital in Wuhan, China, which was constructed in January in just 14 days.

The new solution will offer a turnkey digital-thread and modular-construction platform for deployment of new hospitals at short notice, in less than 100 days. It will cover design of all aspects, from engineering, construction, and procurement, through to operation and maintenance.

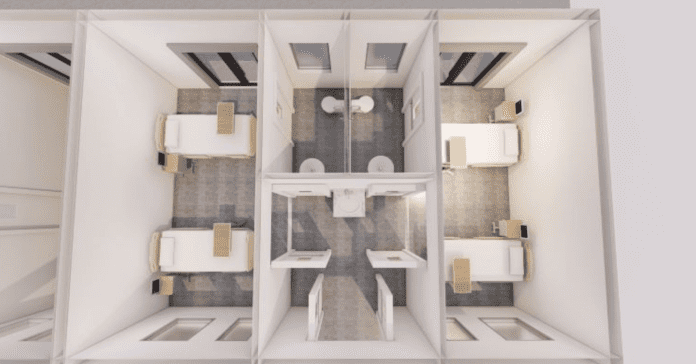

Healthcare providers will be able to use the platform to edit a digital twin of a hospital to their ends, to optimise space planning, module design, isolation rooms and other features, and to simulate manufacturing, equipment, and training.

After construction, the solution will be used for digital asset management by connecting the facility with medical equipment to monitor hygiene procedures and hospital robots.

The pair said they will assemble a consortium of specialists in medical equipment, engineering, and construction to offer the solution to countries needing it most.

Dassault Systèmes is offering its 3D computer-aided design (CAD) platform, called 3DEXPERIENCE, into the bargain; the solution will also leverage Aden Group’s so-called Akila Care smart hospital concept.

Dassault Systèmes stated: “The solution relies on a virtual collaborative environment for the design, simulation, and development of hospitals that can be operational within 100 days and remain operational for many years, as well as for optimising their operations and maintenance throughout their entire lifecycle.”

The company stated the new initiative “comes in light of” the successful setup of the Wuhan hospital in a few days, as part of CSADI’s response to COVID-19. The modular Leishenshan Hospital in Wuhan was created in 14 days, from scratch.

CSADI used the 3DEXPERIENCE platform to simulate virus contamination and diffusion within the hospital’s ventilation system and to counteract the negative effects from unplanned ventilation risks.

Francois Amman, co-founder of Aden Group, said: “In a global context where decisiveness and rapid action are essential to help in the fight against COVID-19, combining quickly buildable modular architecture with a digital platform can accelerate the construction of a cutting-edge medical facility and ensure it is fully operational in record time.

“By using the 3DEXPERIENCE platform, we hope to develop a solution that would enable us to reduce engineering changes, maintain a rapid development schedule, and meet delivery commitments quickly and effectively, as well as ensure long-term hospital maintenance and safety in anticipation of further pandemics.”

Bernard Charlès, vice chairman and chief executive at Dassault Systèmes, said: “We have already shown how simulating virus contamination and diffusion within the Leishenshan hospital’s ventilation system can help to address urgent healthcare needs, and now we will work together to apply our knowledge and know-how to all aspects of the hospital lifecycle.”

He added: “Aden’s approach to outcome-based facility management calls for modular, smart and connected facilities engineered and built with an advanced manufacturing approach. [These] facilities can only be made possible with a virtual twin of the outcome. The 3DEXPERIENCE platform is the catalyst and enabler of such radical transformation, making our alliance a showcase for the future delivery of mission-critical infrastructure.”