The trick with AR in industry is to keep lights on and services flowing even during periods of absence, as enforced in extremis by the new coronavirus pandemic. The kinds of remote assistance tools being offered by companies like Microsoft and PTC, and some of the others interviewed in this paper, bring knowledge and expertise to the coalface of industry.

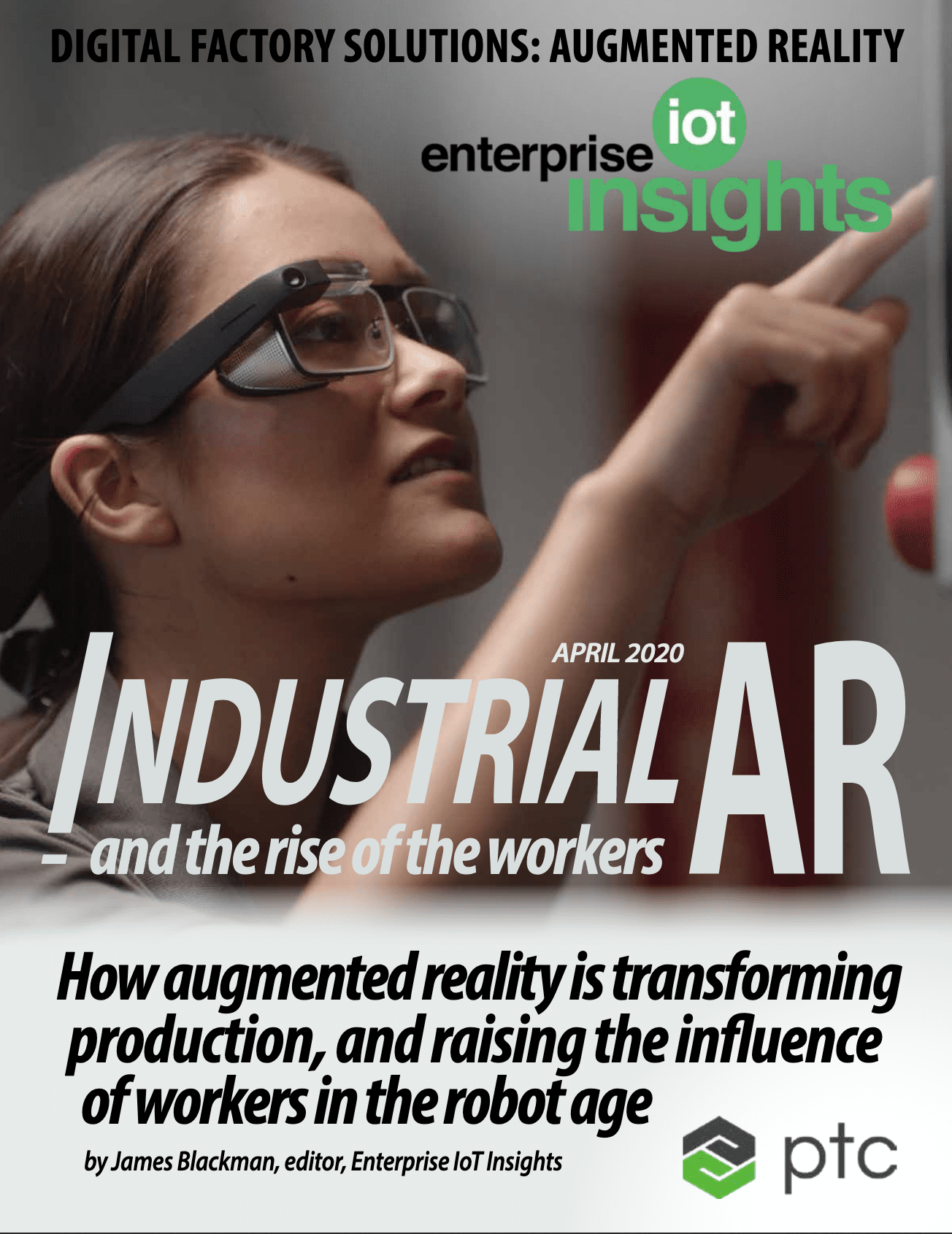

They have seen a surge among industrialists during lock-down, as home-working has been enforced. Demand for AR headsets has been turned up, even as supply chains have been turned down. Industrial AR makes experts of novices, capable of intricate tasks and abstract thinking that robots cannot be trusted with. It offers a counterpoint to the industrial narrative about automation and analytics.

Marc Schuetz, vice president of AR product management, comments in the report: “With AR, we have the opportunity to connect the frontline worker, and provide the right in-formation for the right job at the right time – exactly where the job is done. That is the way the technology is going; that is where the real power is.”

This paper, the latest in Enterprise IoT Insights’ Digital Factory Solutions series, considers the growing power of AR as a work tool in the industrial space, including types of industrial AR, applications of industrial AR, worked ROI calculations for industrial AR, and the challenges that remain for it, particularly around the usability and functionality of AR hardware and difficulty of AR content creation.

James Blackman, editor of Enterprise IoT Insights, comments: “Importantly, and against trend, this new power is for people in industry, and not for machines; it raises the human workforce above its robot peers, and effectively makes AI a servant to its own industrial mastery. That is the big idea, at least; for now, AR remains a niche pursuit, popularised as an easy smartphone-based enterprise tool while the hardware and networking play catch-up.”