In research for a new report on industrial AR, Enterprise IoT Insights caught up with Justin Paul, director of marketing at Zeetta Networks, to discuss the challenges with AR (and VR) setups in the industrial space, as well as Zeetta Networks’ involvement in the UK’s 5G-ENCODE project. Here is the interview, in full; the new report – Industrial AR, and the rise of the workers – is available to download here.

How is AR / VR being used, today, in manufacturing?

“AR is seen as having major applications for Industry 4.0. There are a number of use cases put forward for training, manufacturing, quality control, repair and technical support. There have been AR experiments with remote musicians allowing multiple remote musicians to play together in a synchronised manner.”

How is the experience, today? What works, and what doesn’t?

“AR/VR is the new technology use case that is most reliant upon ultra-low latency. AR or overlays should ideally be less than 5ms latency to avoid user disorientation. High latency can cause disorientation, nausea and vomiting. AR/VR using tablets or screens are less likely to cause disorientation.

“The other challenge is that 360 degree AR/VR requires very high bandwidth. These applications work well in a controlled network with service prioritisation. They do not work well over networks that haven’t been optimised. AR is one of the few use cases that needs ultra-low latency. We want to show that with 5G people can use AR for long periods without disorientation.”

What AR use cases will 5G ENCODE look at?

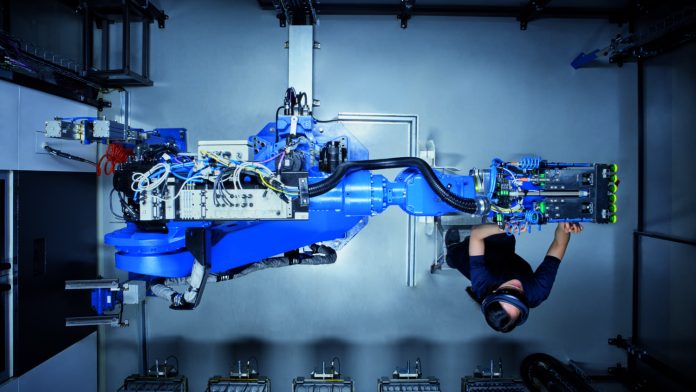

“We are looking at AR being used in both the manufacturing setting and in the classroom for remote technical support. The ability to overlay an engineer’s view with information, instructions and guidance can improve the resolution of issues with complex manufacturing machinery.

“It also enables the machine manufacturers to provide access to very experienced technical support without the need for them to travel to site, which has a carbon footprint benefit, but also has a huge impact in the potential down-time needed to repair machinery.

“It is not a panacea – sometimes parts will have to be shipped, and for the most complex issues these engineers will still have to travel to site but that could be as little as one issue in 20. It has a huge impact on productivity.”

What are the software inputs in terms of digital thread / twins?

“We’re still working through the detailed design for the project. The initial focus is the 5G network, because that is the critical piece to enable all of the use-cases and services. As the project proceeds we’ll be able to talk in more detail about the detail of the use cases.”

What are the requirements on edge processing?

“Edge processing is a key way of driving down latency in a non-optimised network. In last year’s 5G Smart Tourism project, Zeetta used edge-compute to create an optimised network supporting 360-degree video using Wi-Fi and edge compute. Laws of physics ultimately dictate latency. To get to less than 1ms latency you must be within 50 kilometres of where you process.”

Do industrial AR and VR work with Wi-Fi and LTE? How important is industrial 5G?

“Standalone 5G in Release 16 is expected to support the ultra-reliable low latency communication (URLLC) capabilities that will give less than 1ms latencies on 5G networks. However, as Zeetta Networks proved last year, using network optimisation techniques and edge computing it is possible to create low latency Wi-Fi and 4G/LTE networks.

“The 5G Smart Tourism network had around 4-5ms latency using 4G/LTE radio. This is certainly able to support many of the AR/VR industrial use cases. However, in 5G Release 16 it will be easier to crate and manage low latency networks. Wi-Fi has limitations with mobility, but private 4G/LTE networks can support industrial VR/AR. In short, if you know what you’re doing you can support VR/AR latency requirements today.”

Check out the editorial report on industrial AR, Industrial AR – and the rise of the workers. The report is available to download here.