AI-based models facilitate a transition to automated operations using machine vision data

Underpinning the grand vision of a more efficient, productive, sustainable Industry 4.0 is the ability to use sensors of all types to collect information from the physical world. This sensor data can be fed into software powered by artificial intelligence and machine learning where optimal outcomes are determined and action is initiated to achieve that goal–all automatically.

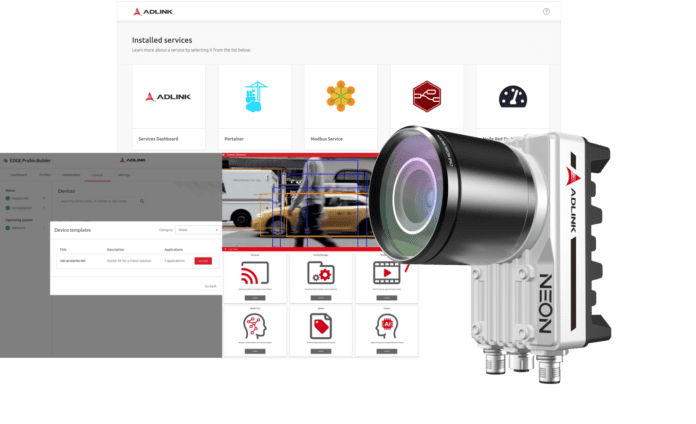

In this Internet of Things-powered world, the camera has emerged as a go-to sensor for many use cases and applications that require a machine or item to be visually monitored–think quality assurance on a production line or remote condition tracking of a manufacturing component. Machine vision is a mainstay in a variety of enterprise and industrial settings but how do you take it to the next level, imbuing intelligence and automation in machine vision systems?

In considering this push to introduce AI to existing machine vision systems, Daniel Collins, senior director of IoT Edge Solutions at ADLINK, described the common need from machine vision experts to automate their systems in a simple, cost-effective manner that lets them focus on business outcomes rather than integration necessary to connect cameras to a model.

“A data scientist is really good at slicing data,” Collins told RCR Wireless News in an interview. “But they don’t know how to collect data. If you give them data, they can find insight. The same is true for machine vision experts. But they don’t know how to put together cameras and the other components. That’s just not their focus. That’s what we do.”

“A data scientist is really good at slicing data,” Collins told RCR Wireless News in an interview. “But they don’t know how to collect data. If you give them data, they can find insight. The same is true for machine vision experts. But they don’t know how to put together cameras and the other components. That’s just not their focus. That’s what we do.”

Rather than dedicating time and resources to connecting cameras for the purposes of developing machine vision models, enterprises can jump right into using those models to automate processes and improve business outcomes. Further, existing investments can be augmented and enhanced rather than ripped and replaced to balance the need for automation with the reality of capital spending.

“We can connect our turnkey machine vision AI solution into any existing system without replacing current processes and machine vision investments, including completely unintelligent and analog systems,” Collins said. “This lets you build machine vision models more easily and quickly–users who are familiar with machine learning platforms don’t need to figure out how to connect to unfamiliar cameras, record training data, determine how to stream images to the models, use those models in a production environment and then make the model take an action.”

“What everybody wants to do, because these systems are already there, is introduce artificial intelligence,” Collins concluded. “This is the most cost-effective way to add AI.”

For more information on ADLINK’s edge and AI solutions for machine vision systems, click here.

About ADLINK: With global headquarters in Taiwan, ADLINK has operations in the United States, UK, Singapore, Beijing, Shanghai, Shenzhen, Japan, Korea and Germany. ADLINK products are currently available in over 40 countries across five continents, with worldwide distribution networks. ADLINK is a leader in edge computing with a mission to affect positive change in society and industry by connecting people, places and assets with artificial intelligence through the delivery of leading EDGE, robust and reliable hardware and software solutions that directly address mission-critical business and technology challenges.