The number of industrial IoT connections will double in volume (up by 107 percent) in the next five years, going from 17.7 billion in 2020 to 36.8 billion in 2025; the manufacturing sector will contribute 22 billion of these, or about 60 percent of the total in the period. Private 5G networks will be “crucial” for smart manufacturing going forward.

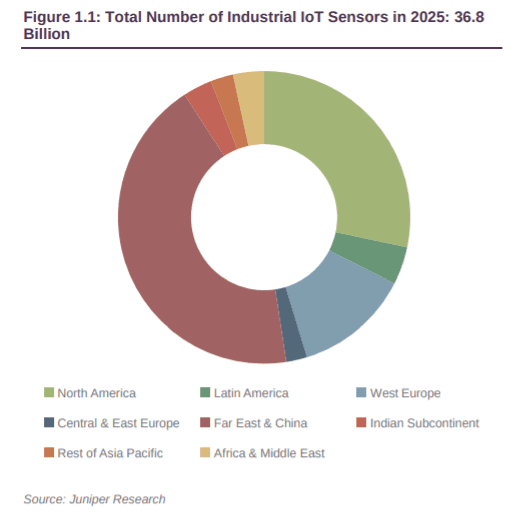

So says analyst house Juniper Research, which reckons the Far East and China will contribute the lion’s share of global connections (about 40-45 percent, at a glance at the pie chart that attends the announcement; see image). North America and Western Europe will contribute (about) 30 percent and 15 percent, respectively.

A free preview of the new Juniper Research whitepaper, featuring the forecast, does not prescribe shares for other industrial sectors; it only suggests agriculture, energy and utilities, logistics, mining, and oil and gas will contribute most of the balance (14.8 billion connections) by 2025.

The company said 80 percent of the value of the industrial IoT market in 2025, worth $216 billion, will be attributable to spending on software. “Software tools leveraging machine learning for enhanced data analysis and the identification of network vulnerabilities are now essential to connected manufacturing operations,” it commented.

5G-based networking will feature prominently, it said, alongside both cellular and non-cellular low-power wide-area (LPWA) technologies, which have a headstart in the animation of industrial processes via lower-level sensor solutions. This dual-mode networking architecture will play a “pivotal role” to enable smart factories.

The company stated: “Private 5G networks will prove most valuable when used for the transmission of large amounts of data in environments with a high density of connections and when significant levels of data are generated. This, in turn, will enable large-scale manufacturers to reduce operational spend through efficiency gains.”

Research author Scarlett Woodford said: “Manufacturers must exercise caution when implementing IoT technology; resisting the temptation to introduce connectivity to all aspects of operations. Instead, manufacturers must focus on the collection of data on the most valuable areas to drive efficiency gains.”