Researcher calls out construction, automotive, healthcare, oil and gas, as verticals that will drive digital twin adoption

While the concept of building a digital twin is not new, GlobalData Principal Disruptive Tech Analyst Kiran Raj sees certain industrial verticals already upping investments around data analysis, IoT, machine learning and, artificial intelligence, increasingly looking to digital twin capabilities to unlock time- and money-saving use cases that nest under the Industry 4.0 umbrella.

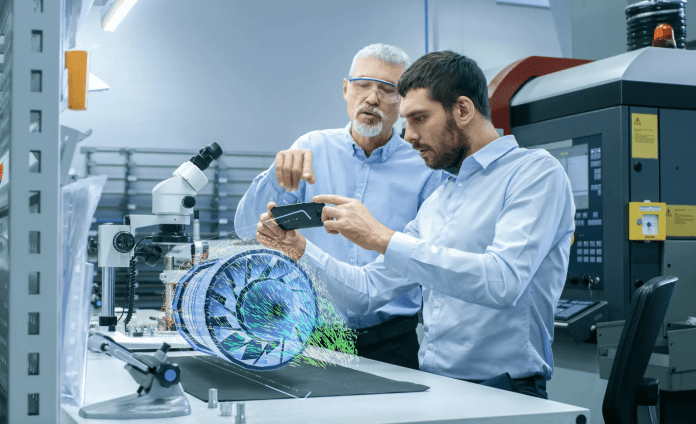

In a research note, Raj highlighted the relevancy of digital twin capabilities—using sensor data and software tools to build virtual models of current and future state physical assets or processes—to product iteration, asset monitoring, improving maintenance regiments, and reducing downtime in industrial environments. The researcher specifically called out the oil and gas, automotive, healthcare, and construction verticals as likely drivers of digital twin adoption.

To the oil and gas example, Royal Dutch Shell last year began a four-year project to construct a digital twin of its Pulau Bukom petrochemical manufacturing site in Singapore. Shell is expecting a 25% increase in productivity, reliability, and safety. The industrial giant plans to take data from 20 different platforms and feed it into the digital twin; they want to use augmented and virtual reality interfaces as the visualization interface. Royal Dutch Shell is targeted use cases that improve operational efficiency, prevent downtime, reduce maintenance and associated costs, and support more effective collaboration between remote experts and in-field operators. Read more about this large-scale digital twin project here.

In addition to gaining “a lot of traction in the last few years due to accelerated digitalization across industries,” Raj said digital twin tech has “become more valuable during the COVID-19 pandemic to help companies navigate the crisis. Startups have the capacity to provide off-the-shelf and bespoke digital twin solutions that enterprises in various industries…can quickly integrate into their business operations.”

“The future of the digital twin technology looks bright in many industries, especially in the industry 4.0 set up where the impact of a product can be assessed before it is manufactured,” RAj said. “But increased reliance on it to aggregate massive data from sensors may make it vulnerable to cyber-attacks. Enterprises with advanced threat mitigation strategies can unlock the true potential of digital twins to enhance agility and innovation.”

For a deeper dive into digital twins and digital threads, check out the following Enterprise IoT Insights report, available for free download: Digital thread and digital twin—translating data into business value.