Note, in the week following publication of this article, Sigfox filed for bankruptcy. Coverage of receivership procedings against Sigfox can be found here; read on to hear about the kind of big ideas that, perhaps, undermined Sigfox in the end – but which also show the bluest-sky thinking in the IoT space, and the theory to deliver ‘massive’ IoT via a race-to-the-bottom on hardware costs.

Sigfox reckons it can get IoT hardware costs down to just 30 cents ($0.30) per unit, with battery life lasting up to 13 years. It suggests it can, on paper, get to this price using printed biodegradable batteries and other circuitry. The claim extends, by some margin, its work so far to move the needle on tracker pricing closer to the magic dollar mark, plunging the race to the bottom on IoT costs (and to the top, in theory, on IoT volumes) into a new dimension.

The firm’s dogged pursuit of dirt-cheap IoT hardware is long-running. A couple of years back, before Covid-19 cancelled the conference circuit, it distributed $1 ‘button’ prototypes, as panic buttons on keychains, to developers at its annual Sigfox Connect event in Singapore. By late 2020, China-based chip firm CMOSTEK Microelectronics had commercialised them for pallet tracking in the supply chain and postal market, where Sigfox has decent contracts.

A second unnamed chip vendor, we were told, was in the wings, promising similarly-specified modules for $1-$1.50. At the time, Sigfox said the units would last three years, to match the shelf-life of pallets and weeks or months in certain ultra-budget cases, with enough power to issue “hundreds of messages”. Both single-usage and reusable versions were to be available, it said; a recycling scheme to counter e-waste was also in development.

Between times, lots has changed. Sigfox has introduced a new category for dollar-range IoT devices, dubbed as U²LC (ultra-ultra low-cost). Nominal pricing for these units, meanwhile, has gone through the floor, and provisional longevity has gone through the roof. It has also, it seems, dispensed with the idea of recycling altogether; all its R&D guns are now turned on recyclable parts, optimal system design, and, to a lesser extent, energy harvesting.

“Deploying ‘massive IoT’ with conventional battery chemistry and conventional [engineering] techniques, without scrutinizing the waste-versus-gain ecological trade-off, would be a catastrophe,” says Christophe Fourtet, co-founder and chief technology officer at Sigfox, in email conversation with Enterprise IoT Insights. His responses are constructive and detailed, and potentially game-changing in their import. They are transposed in full below.

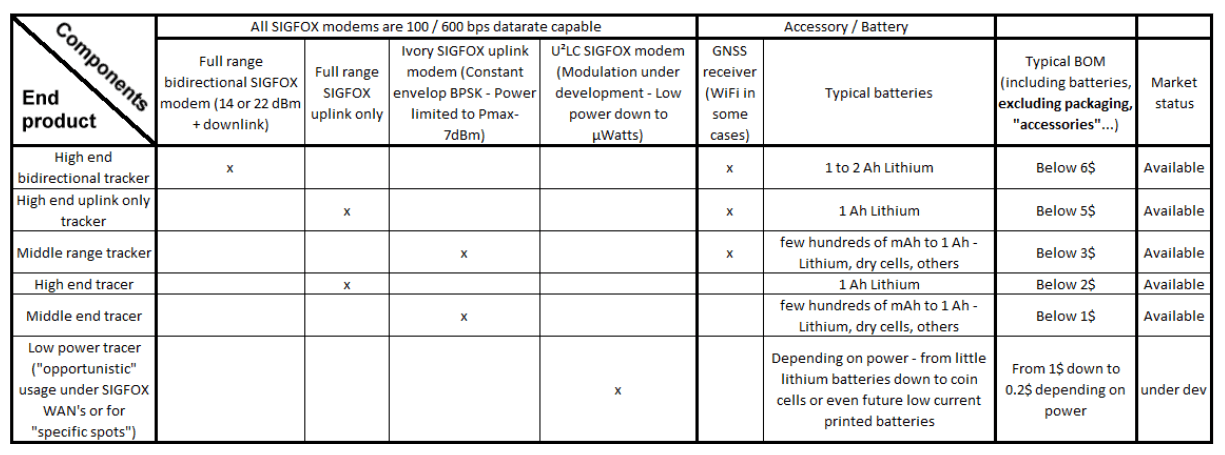

But we should set the record straight, first of all. These U²LC units are not IoT trackers, in fact; they are ‘tracers’ in the Sigfox parlance. As with the 2020-vintage dollar-range CMOSTEK units, and as with dumbed-down trackers on LoRaWAN and cellular IoT, they make certain modifications. Invariably, they dispense with secondary receivers, whether GNSS, Wi-Fi, BLE, or otherwise, used variously to capture positioning data in indoor and outdoor trackers.

Most dispense with a primary radio receiver, as well, leaving them as transmit-only ‘unidirectional’ affairs; often, where network coverage is decent, the front-end power amplifier is also jettisoned. “A ‘tracer’ is a normal [LPWAN] uplink modem that is localized [instead] through trilateration or similar techniques by the network itself. With tracers, the best [result] is rough geolocalization, which can be further improved with additional processing.”

Fourtet says a stripped-back Sigfox tracer can deliver positional read-outs with an accuracy of 100 metres (ranging up to 10 kilometres) in a public wide-area network (WAN) environment. He explains: “But many logistics applications are happy with this [and] there is no additional burden. The price – BOM-wise and most importantly energy-wise – increases drastically with trackers. The ‘tracer’ concept somehow exists in a long-range corner of the RFID world.”

All of which we know, of course; the road to massive IoT will be paved with this kind of slimmed-down U²LC hardware, offering a cold-blooded pulse to animate however-many billions of semi-dormant sensors. There are coverage and complexity issues to sort out, but this is how IoT becomes a no-brainer, and rushes head-long into the enterprise mass-market, giving rein to as-yet unknowable use cases that do not require much thought.

Because everything else – all the red-hot wireless circuitry being set down with private 5G, say, and other higher-grade industrial technologies, and even all the hybrid gadgetry being attached to standard cellular and non-cellular LPWA tracker solutions – requires, often, painstaking planning and budgeting. In the latter case, the mega deals, breaching the million-connections mark, are still not coming so easily.

The enterprise market needs a gimme from the IoT sector; ultra-cheap tracer solutions might just be it. If only the green question, about how to stop from littering the planet with cheap disposable tech, can be answered. Fourtet is good on this subject (see below), reasoning that biodegradable parts and optimised systems (and, somewhere down the line, energy harvesting mechanisms) will make massive IoT easily carbon-negative, in effect. He is also forensic about the theory to get IoT hardware to 30 cents and 13 years.

Just lastly here, before giving the floor over completely to Fourtet; what about those volume numbers? Because Sigfox, lest we forget, with somewhere south of 20 million connections on its network currently, has quoted a frankly bonkers target in these pages before – albeit more as a ‘moon-shot’ to gee-up the troops and stimulate the market – to get to a billion by 2025. So what kind of business does Sigfox expect to deliver, exactly, with ultra-low cost trackers and tracers?

“Volumes could go to hundreds of millions of units per year,” responds Fourtet. Not quite so massive, perhaps; but a major advance on its (and anyone’s) current run-rate – and a somehow more reasonable-sounding moon-shot from someone talking, without any sense of impossibility, about selling (the hardware components in) intelligent radio network solutions for less than the price of postage stamp – and a second-class one at that. But, here’s Fourtet, in full; all the answers below are from him.

…

What use cases will these ultra low-cost trackers be for / open up?

“In logistics, large containers, and lorries in some cases, can justify ‘high-end’ trackers from an ROI standpoint; by contrast, pallets and crates – and certainly parcels – require tracers. But even letter logistics, which is currently considered as a dream [concept], is achievable with U²LC tracers.

“In the industrial space, process optimization – for tracing of tools, crates, goods, machines indoors and outdoors across vast work sites – can also be addressed with ultra low-cost tracers. And livestock and wild-life monitoring, which remains limited to scientific experiments today, will become a reality with lower-cost IoT.

How is this cost-price achieved? What is left out, and what is kept in?

“The whole Sigfox approach is geared towards the simplification of end devices; it is about sophisticated network infrastructure at the service of simple IoT devices. But choices have to be made – about the elimination, for example, of the downlink receiver element, which removes the mandatory electromagnetic shielding and antenna burden, and of the auxiliary GNSS or beacon receiver, which is the case anyway with the tracer model.

“Equally, there is a question about using lower power and simpler modulation, in return for different usage and performance – like a lower success rate in public WAN and a need for denser coverage. But [these compromises on performance] also, often, bring lower power and longer life. And many use cases do not require these additional components – and are greener, effectively, without. It is also worth noting that, with Sigfox, there is no need for a downlink receiver to achieve a high quality-of-service (QoS) because the network itself is massively ‘cognitive’.”

What is their life expectancy, when IoT prices go ultra-low?

“The Sigfox system is unique so far as the lifespan of devices goes, allowing IoT developers to fully predict usage – and therefore power and longevity. This is because the network does not provide QoS through classic network-device protocols, which are subject to fluctuation in device consumption. Instead, QoS is achieved through cognitive properties and massive signal processing in base stations and the network core, as well as through collaborative space diversity and other infrastructure tricks.

“Sigfox devices never negotiate their data rate or modulation. They initiate the downlink by themselves. The infrastructure adapts dynamically to ‘everybody’, in real time – like, the infrastructure compensates for a lack of device ‘discipline’ so the devices are as simple as possible. But as ever in engineering, it requires choices to be made – around data rates (100bps and 600bps), dissymmetry in downlink volumetry, delay in remote control, and so on.

“But the network infrastructure has zero influence on consumption, which is fundamental for low energy IoT devices and long lasting IoT systems. So the lifespan only depends on the usage profile – which is pre-programmed over weeks, months, years – and such things as the battery capacity, and the battery chemistry and packaging reliability in hostile environments.

“To give an idea, a $5 tracker with a 1Ah battery can last:

~8 years at 100bps and ~9.5 years at 600bps for 3 positions per day;

~4 years at 100bps and ~5.5 years at 600bps for 10 positions per day;

~1 year at 100mbps and ~2 years at 600bps for 2 positions per hour.

“By contrast, a $1 tracer with 1Ah battery can last:

~37 years at 100bps and ~83 years at 600bps for 3 positions per day (limited by battery / packaging)

~14 years at 100bps and ~51 years at 600bps for 10 positions per day

~3 years at 100bps and ~16 years at 600bps for 2 positions per hour

~1 year at 100bps and ~6 years at 600bps for 1 position every 10 minutes

“Beyond advantages in the network system, autonomy is still dependent on many parameters. Output power for instance could be a significant parameter if a certain degradation can be accepted. For example, the same tracer devices can work with less-expensive coin cell batteries, or equivalent U²LC power sources, bringing the [hardware] cost even lower, and the lifespan lower with it.

“Using the same matrix, a sub-$ U²LC tracer with a coin cell, or equivalent can last:

~6 years at 100bps and ~13 years at 600bps for 3 positions per day (battery-chemistry permitting)

~2.5 years at 100bps and ~8 years at 600bps for 10 positions per day

~6 months at 100bps and ~2.9 years at 600bps for 2 positions per hour

~70 days at 100mbps and ~1 year at 600bps for 1 position every 10 minutes

“This U²LC model is somewhat opportunistic in a public WAN environment, of course, with many frames potentially being lost. But it would work for enterprises to track ‘points of interest’ within a few kilometres, with the installation of two or three small gateways – working as a kind of RFID extension for IoT apps, for instance. And this U²LC concept leads to a ‘sweet-spot’, potentially, with complete devices priced at less than 30 cents ($0.30), with printed biodegradable batteries and full compatibility with existing infrastructure.

“The tradeoff with a printable battery – or some form of energy harvesting (although I am less optimistic for this in the short-term) – is that battery capacity is fixed at 10mAh and the battery power is limited to a peak current of a few-hundred µA (microamperes), and the [transmission] power to 100 µWatt or so. The coverage range, meanwhile, would go from a few hundred metres to a few kilometres.

“But as you see, as we go from one extreme (600 bps, 1 frame per day) to another (100 bps, 1 frame per 10 minutes), the lifespan ranges from more than 11 years (depending on the battery chemistry) to more than 540 days – and you can still operate one frame per minute at 100mbps and 600mbps for 60 days and 300 days respectively.”

What is the green impact, potentially? What is the risk?

“Deploying ‘massive IoT’ with conventional battery chemistry and conventional [engineering] techniques, without scrutinizing the waste-versus-gain ecological trade-off, would be a catastrophe. We all have in mind today that the pollution from a single car – even from a ‘muscle car’, even a 2000 horsepower air-show Warbird – is not an issue, on its own.

“The issue is the multiplication, in terms of pollution and resources, when it goes to massive scale. It is obvious, of course, but that multiplication has to be worked into the calculation right at the beginning. Which means the ‘green impact’ has to be incorporated into the design phase.”

Will IoT devices be disposable, ever?

“It is a complex problem. Sigfox has done its homework from a system optimization standpoint. But if these devices are to be disposable, then they must also be biodegradable or reusable, or else have support from the recycling sector. The problem is with the battery, in the end – and the packaging. The electronics are almost a detail if the solution is well-tailored to the optimal mission. The battery is the hardest thing to make green.

“Printable batteries – based on paper, glucose, carbon, oxygen – are under development. They will be biodegradable. But the energy and particularly the currents they will deliver will be very limited. Classical batteries are more powerful. They could be recyclable, even today. But they can’t be biodegradable. The question – the age-old question – is about the recovery costs: who is going to pay for the recycling? The industry cannot answer that yet.”

Is Sigfox looking at recyclable / biodegradable parts? Which parts; made from which substances?

“Yes. But the first point, again, has to be to keep the mission as simple as possible. The benefit/sacrifice ratio must be as high as possible, and a central concern from the beginning. Too much gadgetry is bad; post-production simplification is not an option. Beyond this, the battery is the key part. For batteries, simple – not to say ‘natural’ – chemistries are preferred, such as oxygen and carbon molecules, along with a minimal amount of metal – and if possible, as with carbon, no metal at all.

“With the printed circuit board (PCB) and antenna, there is no way today to go too far from epoxy – which is a medium pollutant – for radioelectric and cost issues. But there is a smarter way to reduce the [circuitry] footprint by limiting usage and pushing the printed antenna pattern onto a less polluting material like paper. With hardly any performance reduction, and with clever trade-off, the antenna can be printed on paper with carbon materials. Which avoids ‘plain metal’ antennas – although metal antennas still offer the best performance.

“With regards to the active components, the principle is that smaller components mean fewer pins and less metal – which means a greener outcome. Again, the discipline is to pinpoint the parameters in the use case, and stick to them to keep the silicon content to the bare minimum. The mantra goes: keep RF power as low as possible to avoid GaAs (gallium arsenide), and keep with basic CMOS (complementary metal oxide semiconductor) devices.

“Progress has been made to limit tantalum or chemical capacitors, to the bare minimum – and to eliminate them completely, in some cases, with exclusive use of ceramic capacitors. Printed components are also coming. The other thing is packaging, and the use of polluting plastics. ‘Natural’ biodegradable plastics – based on corn, for instance – are now available, [sometimes] with interesting mechanical and industrial characteristics. But they are less durable. Increasingly, we are looking at direct integration into the material body of the final product – such as the pallet, crate, trashcan, machine, whatever.”

What are the near-term prospects for energy harvesting? How soon?

“We are less confident in the short term. The most compatible wireless tech is ambient RF (radio frequency) energy harvesting, but it remains hugely challenging. The market is unclear. Most other methods – thermo-electric cooling devices, turbines, voltage step-up converters – are too expensive, still, and seem only to be for niches. Ultra-low-cost solar/light harvesters are available, and on some IoT products – as are low-cost aero-wind harvesters.

“They often require a small battery buffer, and an amount of surface space. But when the climate and the space allow, they are one of the best options, delivering energy at a nominal voltage, and minimizing energy conversion electronics to almost nothing. All the other options – like vibration, friction, temperature, RF – are very weak and require costly energy converters/accumulators.”

Is the functionality and application of IoT devices limited with energy harvesting? How limited?

“Definitely. There is no chance, probably, that energy harvesting IoT devices will provide the same features as power-supplied IoT devices for the next few decades. Once again, the focus has to be on the minimum hardware for the greatest benefit. There is no room for surplus gadgetry. A system approach is essential.”

Is Sigfox confident massive IoT can also be sustainable and environmentally-friendly IoT?

“Yes, but only by taking an ‘ecological’ approach. And I mean that from an etymological standpoint – to look at the whole system, and consider how it interacts within its environment. It has to be a whole-system approach, where the sacrifice and the benefit is deeply scrutinized. The best engineering is about deciding what to chuck out. Which has been the Sigfox DNA from the start, and has to be the guiding principle for IoT going forward.”