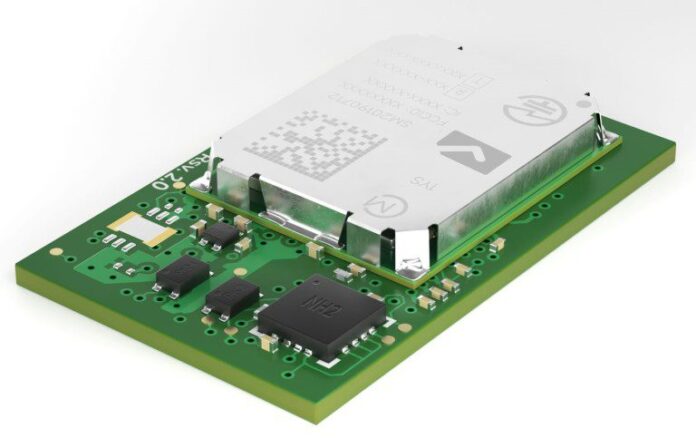

Deutsche Telekom has teamed up with Japanese module maker Murata and Dutch chip company Nowi on a small-sized energy-harvesting NB-IoT module (pictured) that uses the German operator’s proprietary iSIM solution, NuSIM. The trio have called it the world’s smallest battery-less NB-IoT module; it has been presented this week at MWC as an Autonomous NB-IoT Development Solution (ANDS).

The ANDS product, designed for space constrained applications, combines a Murata NB-IoT (1YS) module and a Deutsche Telekom NB-IoT NuSIM, plus a power-management IC (PMIC) from Nowi, which is arguably the key party in the production. Nowi has similar work with Sigfox; it has also engaged with Huawei and HiSilicon, among others, previously. The recent Sigfox solution, with Brazil-based HT Micron in place of Murata, has a similar setup.

The Nowi PMIC extracts power from ambient energy sources like light and vibration to charge a variety of energy storage elements such as a rechargeable battery or a capacitor. The trio have issued a white paper, available here, to present and explain their solution “to encourage more widespread IoT proliferation”.

A statement said: “Industry analysts have made ambitious projections about how many IoT nodes they expected would be in operation with certain timeframes. Unfortunately, the sort of figures envisaged are yet to actually be realized. Currently we are still at a stage where proof of concept IoT projects are being evaluated, and relatively small implementations are being undertaken in some disjoint sectors. This is still a long way from what had been originally hoped for.”

The barrier for massive IoT, until now, has been price and complexity. But these are being put right, progressively. IoT costs are coming down – to as low as a couple of dollars, and ever-closer to the magic dollar mark, for hardware and to about a dollar-per-year for airtime. There are other fees, too, but these are being hammered out and hammered down in clearer total-cost-of-ownership (TCO) calculations.

Meanwhile, complexity is being abstracted all the time; the design-once (deploy anywhere) mantra is starting to work for airtime, through flat-rate pricing, international roaming and integrated SIM (iSIM) rollout, and also for software development, as the low-code/no-code movement (and tiny ML trend) makes machine learning (ML) accessible (and portable to the device-edge), and open app interfaces (APIs) untangle the mad web of IoT airtime standards.

But alarm bells are ringing about the potential environmental impact as IoT gets cheaper and easier, and the IoT industry looks to make good on its promise of large volumes of connected sensors. Because at a couple of dollars each, when the ROI becomes irrefutable, there is little appetite for battery replacements and truck rolls every few years. There is talk about using alkaline batteries, instead of lithium batteries, which are “dissolvable”; the same for the other printed components, bar the chip, which can be retrieved, the industry thinks.

There is also talk about using biodegradable plastics made from fish scales for the substrate (wafer) in the chips. Such innovations are hopeful, but they all tend to look at the problem for massive IoT – and electronics, in general – from the old viewpoint. The concept of energy harvesting, however, seeks to get rid of the battery altogether. In the end, massive IoT is not being held back just by cost and complexity, says Nowi, but by the existential issue of its environmental impact.

If the IoT industry cannot answer the green question, it cannot move forward, the company’s chief executive, Simon van der Jagt, told Enterprise IoT Insights in January. And the only way to do that, he argues, is by jettisoning the battery to harness natural power sources. Responding to a question about whether massive IoT can also be green IoT, he said: “I think the question is more the opposite; can massive IoT exist without being green?”

He said: Green in this context effectively means a low-cost-of-ownership as it eliminates the need for battery changes. Currently IoT solutions are often either limited in functionality or in operational costs due to their power constraints. Vendors can choose to limit functionality – such as the number of transmissions per day – in order to prolong battery life, or [else] try to incorporate the costs of battery changes into their business models. In practice, both [options] are… prohibitive for mass deployments. Many high-volume applications will require energy harvesting in order to be economically viable. As such, it is not a nice-to-have, but a need-to-have.”

The rest of the interview with van der Jagt is available here.