The telecommunications industry is no stranger to sustainability development and goals. It is one of the first sectors to surpass the 20% target for the net-zero target by 2050 set by the United Nations (UN). Based on a recent GSMA report, operators accounting for more than 60% of industry revenue have committed to science-based targets. In addition, operators are one of the forerunners in leveraging renewable energy sources — they are currently about 11% above the market average for sustainable energy-sourced supplies, according to Oliver Wyman’s report.

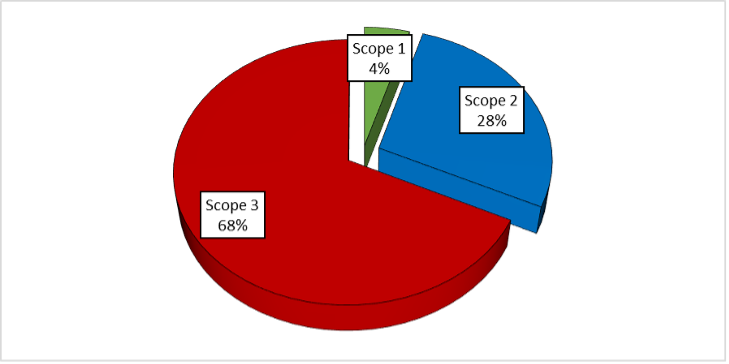

Emissions can be categorized into three “scopes.” Scope 1 and Scope 2 come mainly from the purchase of electricity or energy needed for Mobile Network Operators (MNOs) to operate their cellular networks and operations. These account for about one-third of the total emissions by the industry, while Scope 3 accounts for the rest. Scope 3 emissions are attributed to an MNO’s supply chain, such as capital goods (i.e., plant, property and equipment), or upstream fuel and energy usage, which are out of the MNO’s control.

Chart 1: Telecommunications Operator Emissions Breakdown

MNOs’ cellular infrastructure has multiple network components, including masts, antennas and the radio units for the base stations, as well as the cabinets that house the baseband units. Globally, it is estimated that there are about 7 million cell sites where base stations for one or more operators can be found. The “antenna” is an essential piece of equipment in the Radio Access Network (RAN) infrastructure. It performs the crucial role of transmitting and receiving signals to and from the end-user devices. A single cell site can have an average of two to three macro base station antennas per sector. Furthermore, there are typically three sectors per macro cell site, but that can go as high as nine or even 12.

The mobile industry has traditionally been operating with a “rip-and-replace” antenna policy for every wireless generation, which contributes to unnecessary wastage. This is on top of the manufacturing emissions that come from the production of the antenna unit itself. However, MNOs are aware of the need to reduce Scope 3 emissions. For example, Vodafone Group and Deutsche Telekom are committed to fully abating Scope 3 carbon emissions by 2040, while Verizon has set a target to reduce absolute Scope 3 emissions by 40% from its supply chain by 2035 over the 2019 baseline.

Tackling sustainability in four key reas

To address environmental problems and to be a champion for sustainability, it is necessary to tackle Scope 3 emissions, and yet Scope 3 emissions are the most challenging to tackle. It requires intensive Research and Development (R&D), a new perspective and new processes. There are four areas where innovations in the antenna can play a part in the sustainability journey to help the industry reach its goal: 1) manufacturing; 2) materials selection; 3) deployment; and 4) operational.

Manufacturing + Materials Process

Base station antennas are complex pieces of equipment that require electroplating and soldering, among other processes. Manufacturing is often a major contributor to carbon emissions. The electroplating process consumes significant amounts of electricity and generates airborne and waterborne pollution and physical waste. Tackling this pollution requires the company to implement additional cleanup measures post-manufacturing, which further complicates the process of reducing carbon emissions. Therefore, it is essential for antenna manufacturers to invest in new manufacturing capabilities. There are novel and innovative manufacturing processes that can reduce the number of pollutants generated and also increase overall efficiency (e.g., reduced wastage in materials, water and electricity).

Aside from the manufacturing process, materials selection and the design of base station antennas are part of the equation. Base station antennas use materials like plastics that are challenging to recycle. ABI Research reached out to antenna manufacturers, and Huawei commented that there are more than 3 Kilograms (kg) of plastic parts in a 2-Low/4-High six-band antenna. As mobile operators add more frequency bands (low, mid and high bands), the number of bands supported per antenna will also have to increase. This could result in a potential increase in plastic usage. Innovations at the design stage can help improve the green credentials of antennas.

Design Process

To further reduce carbon emissions, changes made to the intrinsic design of base station antennas can help swap out materials and reduce energy consumption. For example, having complex circuitry within the base station antenna reduces energy efficiency. Reduced energy supplied to the antenna dipole also leads to degradation in performance of the base station antenna. Using an integrated design, such as Signal Direct Injection Feeding (SDIF), helps reduce the number of components, coaxial cables and complexity, improving the overall energy efficiency.

Another design initiative is to enhance the flexibility of base station antennas and their longevity by adopting a modular design approach. This means a base station antenna can be broken down into independent modules for different frequency bands and be customized to meet the needs of each base station deployment. Different frequency bands, such as a low band and a mid band, have their own physical characteristics (i.e., the spacing between dipoles). As the network and its requirements evolve, MNOs can swap out the independent antenna modules to support future needs. This modular antenna approach can keep the wholesale rip and replace practice of antennas to a minimum.

Deployment Process

A cell site requires several components, such as the radio unit, base station antenna, and its associated equipment. Jumper cables are used to connect the radio unit to the base station antenna. However, with the increase in the length of the jumper cable, its electrical efficiency drops due to energy loss. Energy loss can vary between 6% and 25% depending the on the length for a 1.27 Centimeter (cm) jumper cable. Therefore, to improve the antenna performance and energy efficiency, antenna vendors should try to reduce the length of the jumper cable as much as possible.

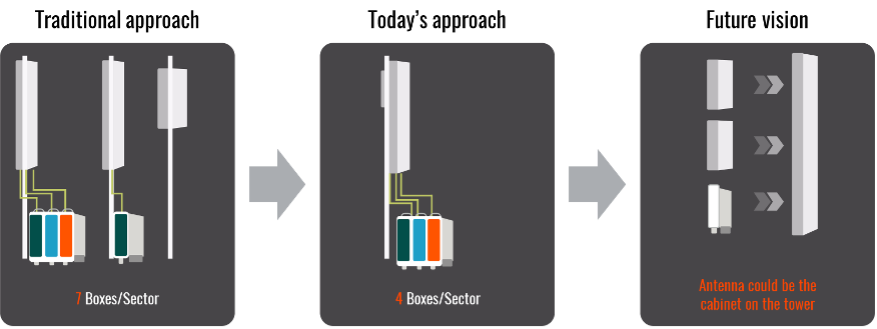

With the introduction of 5G, MNOs have a new product in their arsenal — the Massive Multiple Input, Multiple Output (mMIMO) antenna. However, additional space on the pole or tower is required to deploy mMIMO antennas, which adds to the overall cost of deployment. Simplifying the deployment process by implementing an integrated solution that incorporates the mMIMO antenna, the radio unit, and any required passive base station antennas can help reduce the amount of labor needed for installation, as well as the amount of equipment on the cell site, thereby reducing the cell site’s carbon footprint.

Figure 1: Future Evolution of Cell Site Deployment

Operational Process

There is another domain that is ripe for improvement — the MNO’s operational phase. Traditionally, base station antennas are fixed in terms of capabilities once the design and manufacturing are completed. This limits the longevity of the base station antenna and keeps the practice of rip and replace very much intact. Not all components can be made modular, and they will succumb to obsolescence or degradation, but it is possible to lengthen its life span. One possibility is to tap into Software-Defined Antenna (SDA) technology that can support different sectorization and beamforming capabilities and perform software upgrades remotely.

Never an easy journey, but imaginations will drive the next stage

MNOs like Vodafone Group, Deutsche Telekom, and Verizon, among others, have set targets to tackle Scope 3 emissions. As buyers of the equipment, MNOs often need to kickstart the journey toward net-zero carbon emissions. Cellular networks, similar to utility services, are crucial for our modern way of life and they play an important role in connecting individuals, families, and, increasingly, the enterprise sector. Due to the large installed base of macro cell sites globally, any reduction in the size, weight, number of modular components, etc. can help cut carbon emissions.

Scope 3 emissions consist not only of the physical equipment, but also the energy and fuel usage from MNOs’ supply chain. To reduce Scope 3 emissions, it is necessary to tackle the issues end-to-end in terms of the product’s energy efficiency, as well as its manufacturing and materials. Complex and technologically advanced base station antennas are increasingly required to meet the expectations of MNOs and their consumers. It is expected that base station antennas will need to support more than six bands. By implementing innovations in the manufacturing process and the number of materials used, and switching to more streamlined designs, it will be possible for a reduction in the raw materials used and in the amount of carbon emissions generated.

The telecoms industry needs to continue to find new ways to implement sustainable practices within the core network and the RAN domain. Given the number of antennas needed globally, antenna vendors will need to invest and drive innovations in the manufacturing process and materials used, while extending equipment longevity.