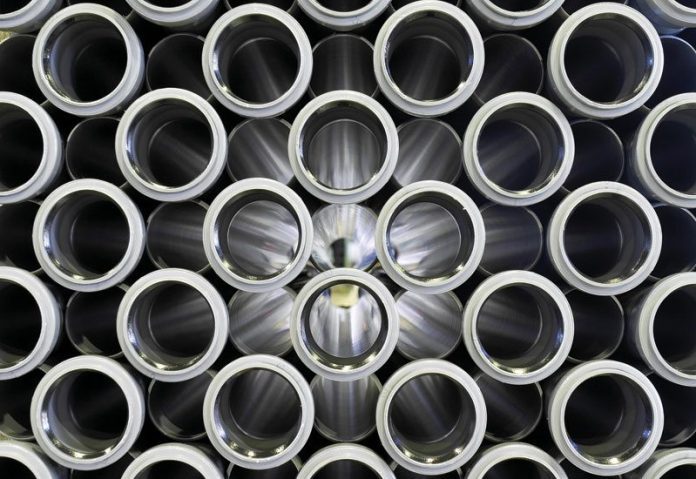

The use of 5G technologies can enhance the safety and security of the workers at the steel plant

The Steel Authority of India Limited’s (SAIL) Bokaro Steel Plant (BSL) has signed a Memorandum of Understanding (MoU) with Telecommunications Consultants India Limited (TCIL) with the aim of exploring the potential of 5G and other wireless communication technologies in the steel manufacturing process.

The partnership between SAIL-BSL and TCIL will offer solutions to SAIL mines and coal facilities in Jharkhand and other areas besides the steel plant.

Alka Selot Asthana, executive director for IT and Telecom at TCIL, said that the firm has the expertise, experience, and resources to provide turnkey solutions for deployment, testing, commissioning and maintenance of 5G technologies for SAIL-BSL.

This partnership will enable SAIL-BSL to leverage the potential of 5G technologies to improve steel production efficiency, reduce costs and enhance quality. The use of 5G technologies can also enhance the safety and security of the workers at the steel plant and its mines, the partners said.

Through the deployment of 5G technology, SAIL-BSL will be able to connect and control its various units and processes, including the blast furnaces, rolling mills and other critical systems, in real time. This will enable SAIL-BSL to collect and analyze vast amounts of data from the steel plant and its mines, enabling it to make data-driven decisions to optimize its production processes.

The steel industry is actively starting to see the benefits of adopting 5G tech to improve operations. Earlier this year, ArcelorMittal France announced the operational launch of 5G Steel, which it claims is the largest 4G/5G network in the industrial space. Partners in the project include Orange Business Services and Ericsson.

The initiative, supported by the French government, is already enabling the first industrial use cases to be implemented at the ArcelorMittal site in Dunkirk.

Ericsson noted that the industrial use cases of 5G Steel include the use of tablets to carry out inspections during maintenance operations, safety audits and lockout procedures.

Also, Ericsson noted that ArcelorMittal’s recycled steel yard management is facilitated by the extensive coverage and high throughput. Steel arriving at the site for recycling is weighed and scanned to assess its density and composition. This data is then automatically transmitted by the operators in charge of quality control from the field via 5G Steel. Operators of cranes and stackers receive the information directly from the production program and can inform about the actions taken through 5G Steel.

Future industrial use cases to be developed on ArcelorMittal’s sites include other initiatives in terms of mobility of people in work situations, autonomous rail vehicles in Dunkerque and Florange, autonomous road vehicles, the generalization of mobile maintenance with field information feedback, virtual or augmented reality and safety devices.