US materials science and digital identification company Avery Dennison is working with European mattress manufacturer Aquinos Group to tag bedding products from 2024 with radio frequency identification (RFID) technology so fewer go to waste, and the company plays an active role in the circular economy, according to a press statement. The project will make Aquinos the first company in its sector to comply with new European Union (EU) Digital Product Passport (DPP) rules.

Avery Dennison makes labeling materials, bonding solutions, and tagging solutions for industrial, medical, and retail applications. It has engaged RFID specialist TripleR on the project. Aquinos Group is one of Europe’s largest mattress manufacturers and operates 20 European factories. It sells products under the BEKA, Lattoflex, Schlaraffia, Sembella, Superba, and Swissflex mattress brands. It forecasts RFID tags will be used in one million of its mattresses by 2027, and “usher in a new era of transparency and circularity” for the firm.

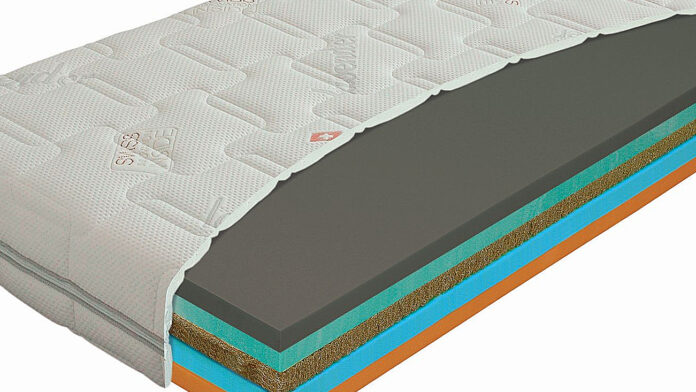

Data from the RFID tags will connect to Avery Dennison’s atma.io platform via RFID readers as they are scanned, creating a digital twin of their whereabouts and history. Data will show information about the origins and materials used in the production of the mattresses. They will also be scanned at recycling centres so that “product dismantlers” can separate materials from the mattresses more efficiently for recycling, and reuse. Consumers will also be able to scan QR codes with smartphones to access product information before and after purchase.

The EU’s new DPP rules will deliver information about products’ environmental sustainability, accessible by scanning a data carrier. Data will include attributes such as the durability and reparability, the recycled content or the availability of spare parts of a product. The DPP scheme is due to come into force for mattresses in 2027. By then, it will have already shipped a million tagged units, it reckons. DPP rules for mattresses will be active sooner in certain European markets, such as Belgium (by 2025), where Aquinos is based.

Aquinos said it will be the “first producer to comply with the DPP scheme at a pan-EU scale”. Aquinos and TripleR are in alliance with the Belgian industry association Valumat as part of a collaboration that also includes product dismantlers.

Benjamin Marien, international commercial director for bedding at Aquinos, said: “DPP sets the next important step in circularity. By being the first in the industry to begin compliance, we want to lead by example to inspire the markets, our industry partners, and the bedding sector to advance environmentally responsible practices…. We will use the power of [our] brands to raise external awareness of the importance of DPPs… We are moving bedding sustainability beyond niche implementation to mainstream. This will be crucial to put an end to bedding materials going to waste.”

Michael Goller, senior director for atma.io at Avery Dennison, said: “We are proud to be working on this project with Aquinos and TripleR. Mattresses are complex and bulky products that require a highly sophisticated sorting and dismantling process. To date, it has proven difficult to do this in a cost-efficient manner – leading to millions of mattresses going to landfill each year. This is precisely why DPPs have been established and we are excited to push boundaries with our partners towards greater traceability, efficiency, and circularity.”

Stefaan Cognie, co-founder at TripleR, commented: “This project is an important milestone and sets a benchmark for how the DPP scheme will operate across Europe to enable sustainability and circularity. We have already developed a digital Identification standard in the bedding industry in Belgium and are engaging with extended producer responsibility (EPR) bodies and mattress associations in different European countries, as well as with the overarching European Mattress Association EBIA to bring DPP compliance to fruition.”