EXFO and Verizon on how to effectively resolve PIM issues that impact network performance and drive up opex

Passive intermodulation (PIM) is a huge headache for mobile network operators. PIM can materially impact network performance while also costing operators time and money as they work to identify the source and work towards a fix. Speaking during the recent Test and Measurement Forum (available on demand here), EXFO’s Danny Sleiman, business development manager for global 5G strategy, said that today resolution of PIM issues takes 2.5 site visits with an average of 12 hours to resolve trouble tickets. Additionally, in two out of three cases, antennas are unnecessarily replaced.

PIM comes in two flavors. Internal PIM results from an operator’s own system–things like bad cabling or damaged connectors, and is typically confined to single network branches. External PIM generally impacts multiple branches and comes from things like consumer signal boosters close to cell sites, oscillating repeaters, foreign wireless devices or even electronic signs.

From the operator perspective, Verizon Associate Fellow Dennis Mccoll laid it out: “There’s a hyper focus on operational expense…The operational expense associated with RF systems is large, and as we add frequencies, as we add power, the problems associated with PIM go non-linear. If you’re going to affect your opex numbers, you’re certainly going to have to be on point when it comes to RF issues, and PIM is certainly one of those things, especially external PIM.”

He called for a number of adjustments that would help operators more time- and cost-effectively address PIM and the problems it creates. First things first, operators need to be able to correctly identify PIM as opposed to some other type of external interference “otherwise you’re going to start dispatching contractors for tower climbs or to do interference work. If you misidentify what’s happening. That’s waste; that’s a large waste.”

Another best practice, Mccoll said, is thinking about PIM when deploying new sites. In the real world that would mean putting antennas on the outside edges of buildings, not inside the parapet, and avoiding known PIM-causing parts in favor of PIM-free alternatives. “It seems very straightforward, but we’re not in this practice. We should certainly be designing sites with PIM-free hardware.” He described this as “PIM hygiene.”

When it comes to external PIM, Mccoll said it’s important to only engage with certified contractors who have had the requisite training and hands-on experience. “We absolutely as an industry need to communicate the need for certification for external PIM specifically.”

Troubleshooting PIM with RF over CPRI analysis

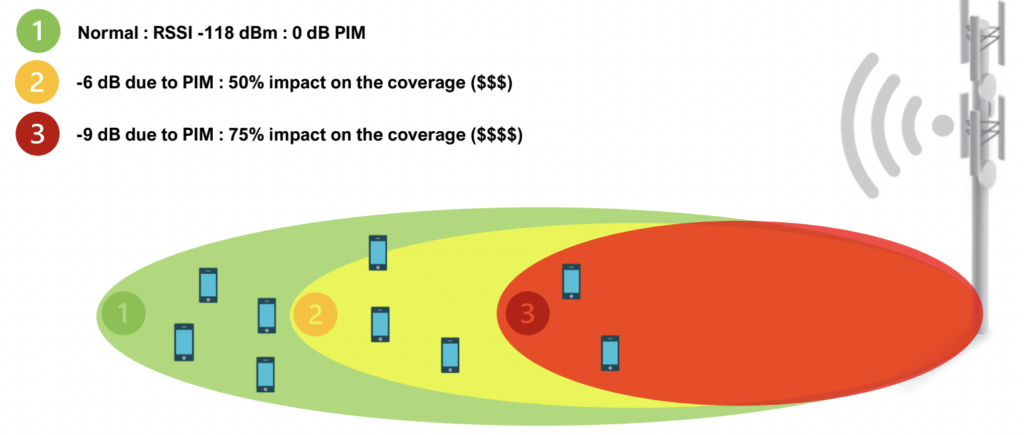

Sleiman agreed with the idea that it all starts with PIM hygiene but, in terms of troubleshooting, he highlighted EXFO’s approach of tapping into the CPRI connection between a base station and radio to analyze PIM’s impact on RF and network performance. He also pointed out that increasing levels of PIM can have a huge (non-linear as Mccoll said) impact on per site coverage.

He laid out “a trusted method of troubleshooting PIM…The first thing that needs to be done is, ‘Can you resolve this PIM issue without pulling any equipment?’” From there, techs should determine if it’s internal or external, then follow the flow chart from there. “If you follow every step and you use the right tools, you’re going to get to a point where you close your ticket and you’re not going to have any unnecessary costs…and no radios being replaced.”

Discussing the RF over CPRI approach, Sleiman pointed out that the site remains operational during the test phase, and because there’s no need to disconnect any RF connections, there’s less opportunity to introduce new PIM. Because the site stays active, techs can see improvements or degradations as they’re happening. “This can be done in under 20 minutes. You’re able to know [if] you have an internal issue or an external issue…The improvements that are done on the site using your test equipment and the CPRI analyzer method will result in KPI improvements to your system.”

Recall Sleiman’s earlier figures around PIM. He said that with the CPRI analyzer method, the average of 2.5 site visits drops to 1.5 site visits, the time to resolution drops from 12 hours to six hours on average, and instead of unnecessarily replacing two out of three antennas, it’s not necessarily to replace any antennas.

Does AI/ML have a role to play?

Mccoll said that using AI would require development of a model whereas many of these type of problems boil down to simple math. On AI, “In many cases, you just don’t need it because there’s very simple ways to go after these things.” He also pointed out that automation tooling mis-categorizing problems is currently an issue operators have to deal with. “Id’ be worried about the use of AI to replace workers…Why are we wanting to go use AI? Is it to make things better or is it to improve the bottomline?”

Sleiman acknowledged that AI has some place here but, at the end of the day, “It’s tough to pinpoint exactly where’s the issue.” AI can be used to simplify configuration and some aspects of troubleshooting but “to identify exactly that location or what it is, it’s hard to do, or practically impossible” using AI versus experienced technicians equipped with the right tools.