Huawei carried out this project in Thailand in partnership with Midea, AIS and China Unicom

Chinese vendor Huawei, together with appliance manufacturer Midea, Thai telco AIS and Chinese operator China Unicom have jointly implemented what it claims to be the first 5G fully-connected factory in Southeast Asia.

Huawei said that the project takes advantage of the 5G network coverage of the Midea Industrial Park in Chonburi, Thailand and a 5G-Advanced industrial internet platform, which is already enabling each production phase of the facility to be seamlessly connected through 5G terminals to enable faster machine operation.

The vendor also explained that a dedicated 5G private network has been deployed to support factory operation requirements and leverage intelligent industry applications, which facilitates manufacturing scenarios and interconnects each production line.

Huawei said that the combination of massive connections and high reliability offered by 5G networks enables real-time monitoring and analysis of production devices, while continuous data collection and analysis optimize equipment utilization, mitigate downtime and enhance overall equipment capacity.

Also, the Chinese vendor explained that using 5G technology, Automated Guided Vehicles (AGVs) have undergone a paradigm shift, moving beyond preset routes and physical markers for navigation. The vendor stated that dynamic path planning and real-time environmental data analysis enhance flexibility and adaptability, significantly improving operational efficiency in complex factory environments.

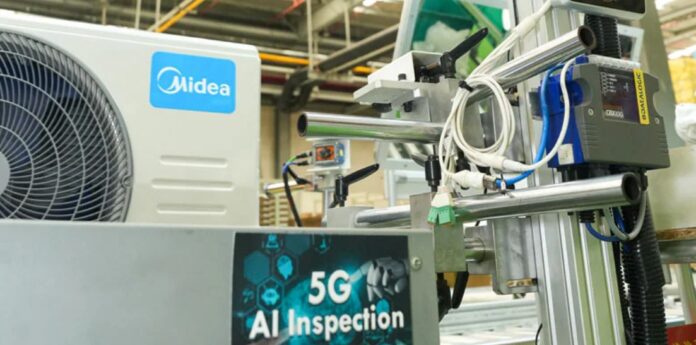

The Thai factory also offers 5G AI inspection, which minimizes operational errors during production phases.

Also, workers are now able to remotely control robotic arms via 5G smartphones, eliminating the need for hazardous manual intervention in the production process, Huaewei added.

The factory also has a 5G “operating room” equipped with 5G technology, which simulates and tests the status of outdoor compressors, ensuring efficient and reliable operations.

Phupa Akavipat, acting chief enterprise business officer at Advanced Info Service (AIS), said: “Compared with other technologies, 5G is the only technology allowing network coverage over 160,000 square meters, covering three production plants. Looking ahead, AIS remains committed to driving innovation and assisting global manufacturers to replicate their smart factory setup in Thailand.”

“We have seen how 5G has played an important role in driving industry transformation. The manufacturing sector has shown significant potential for development and transformation with the adoption of 5G technology. Huawei remains committed to collaborating with industrial customers, operators and partners to generate 5G business value,” said Woragarn Likhitdechasakdi, CTO of Huawei Thailand.

“To achieve this goal, we will actively engage with our customers to understand their digital strategies. By delving into production processes and identifying specific needs, we aim to share valuable experiences and best practices that accelerate the adoption of 5G for intelligent manufacturing upgrades,” the Huawei executive added.