Ericsson noted that this drone is one of the first natively mmWave 5G devices in the factory

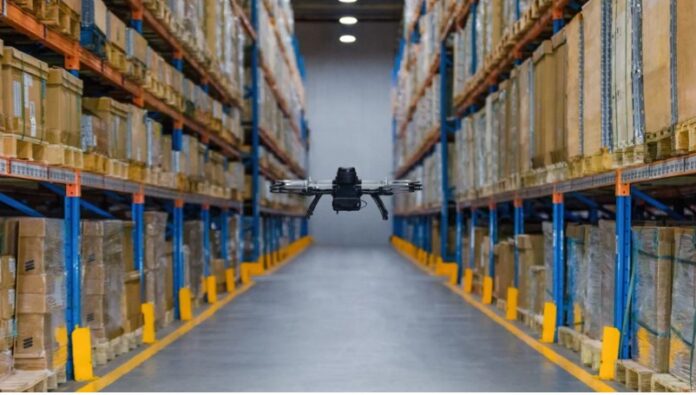

Ericsson has begun a proof of concept with an autonomous 5G mmWave connected drone with the aim of performing indoor activities within the Ericsson 5G smart factory in Texas.

Starting with autonomous inventory checks in the factory’s warehouse high racks, the drone’s indoor-optimized flight control, 5G-connected Nest docking station and live video streaming cameras enable a wide variety of sensing solutions using the Ericsson USA 5G Smart Factory’s 5G private network, the vendor said.

The proof-of-concept showcases the potential for autonomous barcode scanning using drones for inventory management in certain types of warehouses, Ericsson said, adding that the PoC uses a drone, powered by the Qualcomm QRB5165 processor, with integrated 5G mmWave from Telit Cinterion and Ericsson’s end-to-end private 5G network.

The vendor highlighted that this drone is one of the first natively mmWave 5G devices in the factory, signaling a shift from wired or Wi-Fi connections to native mmWave 5G connectivity for industrial use. It eliminates the need for external gateways or hotspots, which were previously required for similar use cases to use mmWave 5G, Ericsson said. A Telit Cinterion FN980m mmWave industrial grade M.2 data card, equipped with the Snapdragon X55 5G Modem-RF System, powers the drone’s 5G connection.

Although the 5G drone test serves as a proof of concept, it is not currently intended to address the needs of the USA 5G Smart Factory, Ericsson said. The demo was focused on showcasing the potential of natively mmWave commercial-ready 5G devices for inventory management in warehouse settings, it added.

Carlos Torres, head of Industry 4.0 at Ericsson’s USA 5G Smart Factory, said: “This successful demo helps lay the foundation for future integration of 5G-powered drones in industrial settings, particularly for inventory management.”

Dev Singh, vice president of business development and head of building, enterprise and industrial automation at Qualcomm Technologies, said: “AI and computing to enable the full potential of Industry 4.0 and beyond. Our 5G mmWave and drone technologies have the potential to transform inventory management, and the successful proof of concept with Ericsson, Dronus and Telit Cinterion demonstrates the practical application of these technologies in an industrial setting.”

Earlier this month, the company announced an additional investment of $50 million, following the initial $100 million investment announced in 2020, to its 5G smart factory in Texas. This additional investment will further accelerate local production to address the demand for locally-made 5G infrastructure, compliant with the Build America Buy America Act (BABAA), Ericsson said.

Ericsson’s highly automated 5G smart factory currently employs more than 500 people. This expansion will allow Ericsson to deliver existing and new radios and basebands (RAN Compute) for major US customers from the US factory, including Open RAN-ready products.

Ericsson’s 5G smart factory opened in 2020 to support the early waves of 5G deployments and has been shipping 5G network products, including 5G and Massive MIMO radios to all tier-one communications service providers in the US.