As the IoT market continues to grow, companies with little or no experience in radio frequency design are seeking to add connectivity to existing products, or design new ones targeting the “internet of things.”

It can be tempting to take wireless connectivity for granted or think that it’s simple when smartphones are nearly ubiquitous and generally reliable. But bringing connectivity to nontraditional wireless devices isn’t necessarily that simple. Here are three of the common pain points in RF design for IoT devices.

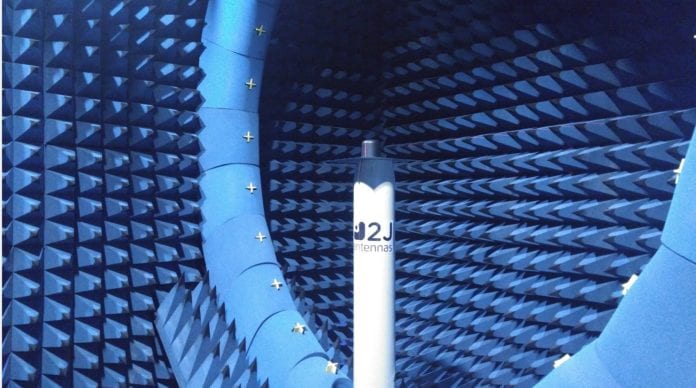

Antenna design

Antennas are often underestimated due to the perception they’re simply a passive component with little impact on overall design. But whether internal or external, antennas are central to performance and whether or not a device will pass certification testing.

Tony Opfermant, business development manager at Rohde& Schwarz, noted if a company wants to have its device work on different frequencies – either multiple bands supported by one carrier, or different bands around the world – that will necessitate different antenna sizes and probably impact design. Low-band cellular spectrum, for example, requires larger antennas than Wi-Fi at 2.4 or 5 GHz.

“In terms of pure physics, it sometimes is tough,” said Ruben Cuadras, engineering manager for 2J Antennas, which designs and manufactures antennas. “There is no way to lie to physics or cheat physics. … In order to have good performance across multiple frequencies, the antenna has to be bigger. That’s in contradiction with the market wanting to go smaller and have multiple technologies and multiple bands, and then low cost. That’s the tough part, especially for embedded applications.”

Noise from other components

Proximity and type of nearby components within an IoT device and how circuit boards are designed can result in interference for IoT RF systems. Device design that doesn’t take into consideration the impact of all components on RF performance can result in certification failure and the need to fix or redesign the product.

“A lot of companies coming from the machine side or even with some networking background, do not have the RF background. RF is black magic for them,” said Mahbubal Alam, CTO and CMO of connected car firm Movimento and a veteran of Cisco’s IoT business. “It’s not a network card, it’s not a USB, it’s not HDMI, it’s not a physical interface. There are noises and channels, and you cannot see them. When two radios are very close, there can be interference and channel noise. If you’re a dedicated sensor, you may be okay – but if you have multiple technologies – Wi-Fi, [near-field communication] and cellular very close to each other, the RF design becomes a huge challenge.”

Cost of test

Despite the growth in IoT, many observers say the cost of testing and certification means the space is not growing as rapidly as it could – in part because the high cost of test presents such a significant hurdle for small and start-up companies, or for small-scale IoT projects. Several experts said test can account for half the cost of a device, particularly for the very low-cost end points such as sensors.

Eric Heiser, who leads strategic partnerships for Ublox, said certification costs are becoming a bigger part of the total cost of test and the value chain of bringing IoT to market. Heiser also said self-certification seems to be an emerging trend.

“If the cost doesn’t come out of this system, you’re never going to get the billions of units,” Heiser said. “And the cost lives in a lot of places, with certification being one.”

“The testing that is performed today on broadband devices is outrageously expensive and exhaustive,” said Eran Eshed, co-founder and VP of marketing for Altair Semiconductor. “I think that for the first time, in the IoT space, it is clear to the carriers that this test strategy has to change.”

For more information on IoT testing, download RCR Wireless News’ free special report on IoT testing.

Image copyright: jpgon / 123RF Stock Photo