Siemens is to integrate Google’s cloud and analytics technologies with its factory automation portfolio. The pair said their offer will help manufacturing companies to move away from fragmented legacy software, and “bring AI/ML to the manufacturing industry at scale”.

Manufacturing companies continue to use legacy software and multiple systems to analyze plant information. This is “resource-intensive”, said Siemens, and requires “frequent manual updates to ensure accuracy”. It said many companies are only deploying artificial intelligence (AI) in silos, or ‘islands’, on the plant floor.

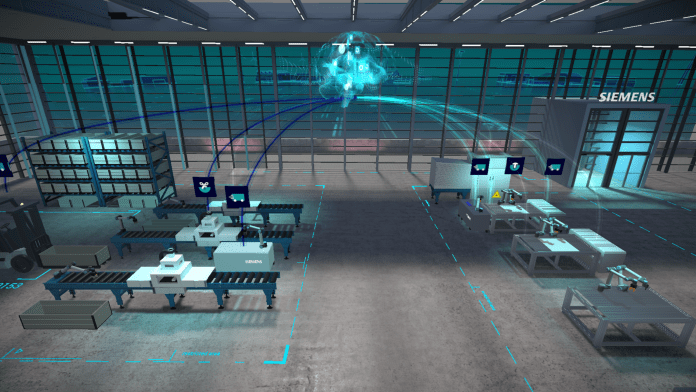

“Manufacturers have struggled to implement AI at scale across their global operations,” they said in a statement. Google and Siemens reckon integration of cloud software and edge hardware, from the two companies respectively, will enable manufacturers to “harmonize” factory data and orchestrate AI/ML between edge and cloud resources.

Automated quality inspections and predictive maintenance were cited as prime use cases. “The goal is to make the deployment of AI in connection with the industrial edge – and its management at scale – easier, empowering employees as they work on the plant floor, automating mundane tasks, and improving overall quality,” they said.

Axel Lorenz, vice president of control for factory automation in Siemens’ digital industries division, said: “The potential for AI to radically transform the plant floor is far from being exhausted. Many manufacturers are still stuck in AI ‘pilot projects’ today – we want to change that. Combining AI/ML from Google with Siemens’ solutions for industrial edge and industrial operation will be a game changer for the manufacturing industry.”

Dominik Wee, managing director for manufacturing and industrial at Google Cloud, said: “This cooperation will combine the best of both worlds and bring AI/ML to the manufacturing industry at scale. By simplifying the deployment of AI in industrial use cases, we’re helping employees augment their critical work on the shop floor.”