Industry 4.0 requires compute and connectivity to be brought closer to the action. This means putting general-duty IT and telecoms equipment into unfamiliar, often harsh OT environments. Chatsworth Products International (CPI) provides the industrial garb, in the form of enclosures and cabinets, to keep this valuable new industrial IoT gear safe.

These edge locations can either be in environmentally controlled colocation facilities, or in non-controlled environments that might contend with heat, humidity, rain, and snow, as well as corrosives and dust. Such deployments require careful storage, support, and maintenance. Below, CPI outlines five principles (‘pillars’) to safeguard new edge setups attached to private LTE and 5G networks.

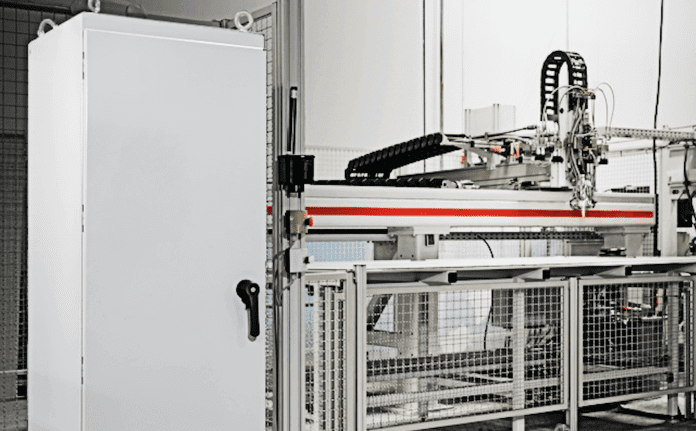

1 | ENVIRONMENTAL CONDITIONS

“The first thing to consider is the environmental conditions – what you need to do to protect all the devices in an enclosure from the outside environment, including the temperature, the contaminants in the air, and so on.”

2 | SECURITY REQUIREMENTS

“The unit has to be lockable, with electronic access controls. We can add sensors, so customers know who is accessing the enclosure, and can send someone out in the event of unauthorised access. The system can be tied in with local security cameras, as well. With the doughnut example (see report, page 22), they would have known if they’d had a sensor on the cabinet.”

3 | KIT AND CABLING

“The third pillar is about the type of equipment going inside – how it is mounted, and the cabling required. With all the servers and storage devices and power supply systems, enclosures are getting larger. We see more 800mm-wide cabinets, ver- sus the standard 600mm [enclosure] – going to a depth of 1200mm. You are still mounting 19-inch (482.6mm) racks in there, but it gives more room for equipment.”

4 | THERMAL MANAGEMENT

“Heat can be dissipated with a filter fan, as the basic cooling mechanism, with the heat going out with the exhaust, or physical ADX air-conditioning units. In some cases, we use air-to-water heat exchangers, with a cooling coil built into the enclosure, and a system that dissipates somewhere outside the building.”

5 | POWER, MONITORING

“Intelligent PDUs and environmental sensors can measure temperature, humidity, airflow, power, intrusion and detect entry of water – useful for edge locations, where remote monitoring can mean the difference between uptime and downtime. PDUs automate monitoring and let you set thresholds and receive alarms when conditions approach limits.”