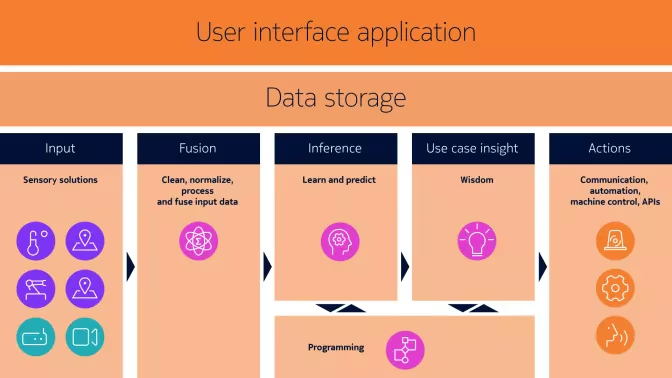

Nokia has added to its burgeoning mission-critical (MX) tech supplies for Industry 4.0 with a new sensor fusion solution to mix multi-modal IoT data streams into an AI engine next to its private 4G/5G system to deliver singular contextual logic for bespoke industrial use cases. The solution, called MX Context, is the first in the market to offer multi-modal sensor fusion, the firm reckons, enabling engineering teams to combine once-siloed IoT data to enhance and create industrial applications. The combination of sensor fusion and AI inference is “also something we haven’t seen anywhere,” the Finnish vendor said in a briefing ahead of the news release.

MX Context works with its industrial edge (MXIE) portfolio, residing on the MXIE edge compute system, which also hosts the core network for its Digital Automation Cloud (DAC) private 4G and 5G product, and knits in with its distributed (far-edge) compute hardware (MX Grid), data-lake storage (MXIE Data Lake), and its generative AI worker-assistant (MX Workmate) – and whatever other MX products Nokia has in the bag (MX Boost etc). It also leans, as required, on Nokia’s own in-house sensor technologies, including its high-accuracy indoor positioning (HAIP; Bluetooth angle-of-arrival) system and new visual position and object detection (VPOD) app.

Third-party GNSS and RFID tracking and positioning solutions such as HERE HD and Nordic ID are also integrated into the offer from the start. All are housed in the MXIE system. Data from existing IoT systems can also be flowed-in, alongside data from common sensors in standard handsets, and other enterprise devices – such as from gyroscopes, accelerometers, microphones, and cameras. New applications will be added to the MXIE menu, as well. Nokia is launching with a tracking and positioning “suite”, which enables enterprises to cross sensor data from all of the above-style devices/applications to devise and develop their own solutions.

A second worker safety suite is close to launch, which fuses most of the same positioning data, plus sundry sensory inputs from staff handhelds and wearables, to apply similar logic and rule to health and safety scenarios. In both cases, the MXIE system can be rigged to act on the MX Context insights – whether by issuing messages or alarms, or linking with MX Workmate, still under development, to generate text instructions for workers. More fusion suites, built on a developing set of modular ‘building blocks’ will be added, the firm said. Nokia is offering a low-code visual developer tool as well so engineers can spin-up new logic workflows and dashboards with minimal coding expertise.

Nokia is to introduce new industrial routers with built-in accelerometers, gyroscopes, voltmeters, and environmental IoT sensors to add further context to the solution’s outputs. They will use advanced GNSS chips for more accurate outdoor positioning, it said. On the briefing call, it explained the value of the solution by describing a factory scenario where the MXIE system gets the idea from a computer vision setup (VPOD camera) on a gantry that a worker has fallen, and the MX Context application cross-checks the data with the shock reading from the accelerometer on the worker’s phone, together with the angle of the leg in the camera data, to confirm the incident, and set off the alarm.

Nokia said: “MX Context is the only solution on the market that provides situational and contextual awareness… It is the first industry solution that can ingest and fuse data from various tracking and positioning technologies. It provides more accurate and reliable positioning and ensures tracking continuity across mixed industrial environments to optimise asset utilisation, inventory management, processes, and material flow… AI-based processing and fusion of real-time data provides, for the first time, situational awareness and contextual information, enabling the detection of potential accidents or incidents and facilitating the best response.”

On the call, Stephane Daeuble, responsible for solutions marketing in Nokia’s enterprise business, explained the complex dynamic Nokia is trying to solve for industrial enterprises. “There is an increasing amount of real time data in customers’ plants – which are very complex environments, anyway, mostly comprising independent systems, and which are subject to new digitalisation, and where new machines and devices are coming in. So they are complex, already, and they are facing complex transformation. That combination brings challenges just to get actionable insights out of all the data – for perfect decision making, automation, and just to enable operations.

“The way the industry has started to solve this, very recently, is with sensor fusion, which allows you to treat and cross data from multiple different sensors – so it can handle multi-modal data, coming from temperature, movement, audio, vision sensors, and whatever. The idea of sensor fusion is to effectively remove all the silos – which is the engine behind this new solution. And because we have all the real time data coming through the MXIE system, and we have these connectors to pull data from anywhere, we can tap into all of the diverse industrial IoT sensors out there, and run the data through a fusion processor, together with an AI/ML [system], to make sense of it all.”

He added: “It gives more insight, and a wider scope. And we believe we have a couple of industry-firsts. The sensor fusion on multi-modal data is something we have not seen in other places. And then, combining sensor fusion with AI inference is also something we haven’t seen. And then, with private wireless, we now have visibility to act upon things. Plus, the low-code programming module is also a new thing. And all of that, combined together, is genuinely valuable and innovative, we think.”

In its press note, Nokia quoted MarketsandMarkets that the global market for sensor fusion will grow at a compound rate (CAGR) of 17.8 percent per year to be worth $18 billion by 2028. It also supplied a quote from Ryan Martin, research director at ABI Research, which said: “Sensor fusion and AI are key capabilities for core industrial automation applications [like] robotics, autonomous work cells, and collaborative scenarios involving humans and machines. Nokia, with its private wireless and on-premise industrial edge compute, is well positioned to offer critical use cases for worker safety and tracking and positioning to bring the power of AI insights to industrial digitalization.”

Stephan Litjens, vice president for enterprise campus edge solutions within Nokia’s cloud and network services business, commented: “AI is becoming a strategic element for Industry 4.0 transformation. Nokia’s on-premise compute capabilities offer innovative AI solutions that are OT-compliant and bring the contextual awareness needed for industrial use cases. Nokia MX Context harmonizes real-time data from sensors and sensing technologies. It takes data-driven operational excellence to the next level, transforming data into contextual awareness information that can be used as actionable insights and intelligent automation.”